您的中国压铸专家

3D Printing to Test Structure

After we confirmed the CAD drawing of your products, we will use 3D printing to make a 3D sample to test the structure and functions.

The 3D printing process allows the creation of parts and/or tools through additive manufacturing at rates much lower than traditional machining.

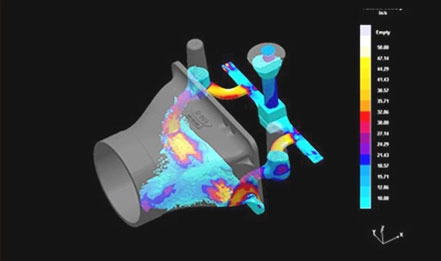

Professional Mold flow Analysis -CAE

Moldflow Adviser providing manufacturability guidance and directional feedback for standard part and mold design and Moldflow Insight which provides definitive results for flow, cooling, and warpage along with support for specialized molding processes.

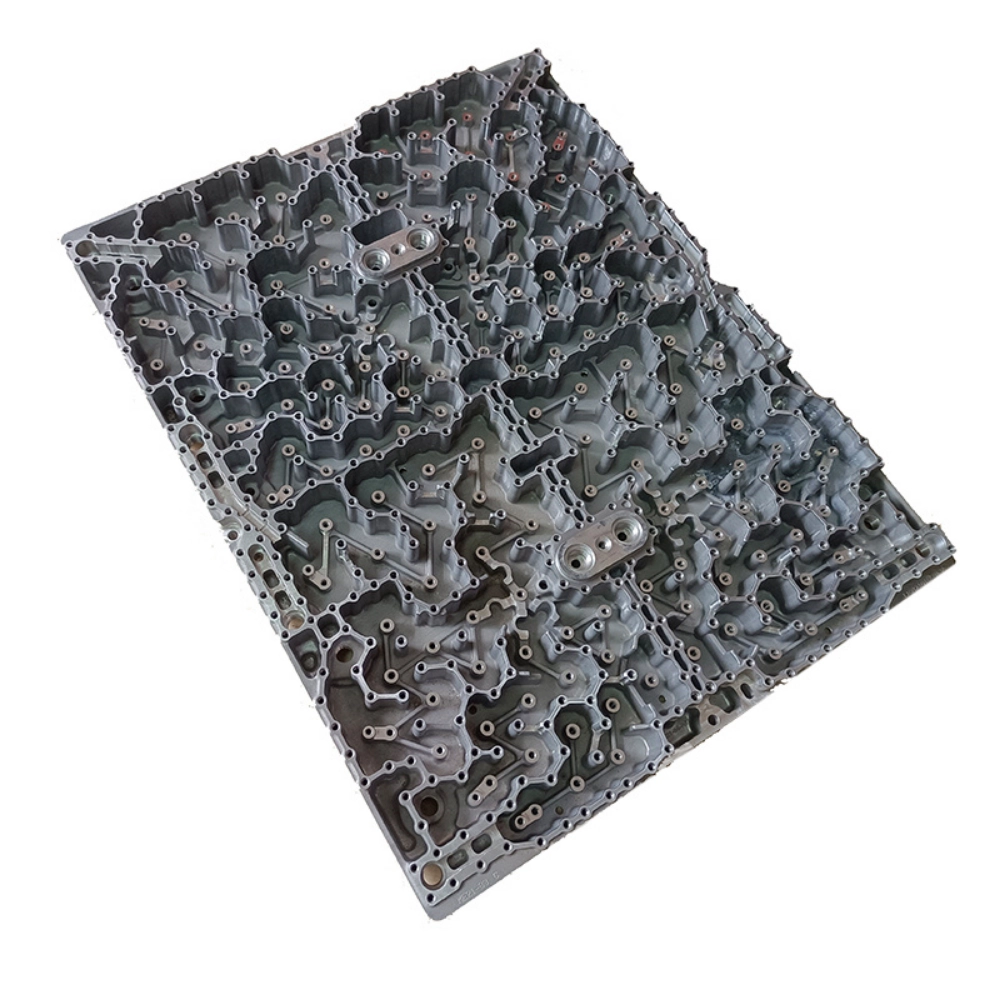

Advanced Die Casting Manufacturing

Die Casting Parts CNC Machining

Experienced engineer DFM the structure before tooling, CAM simulation the CNC route to ensure the allowance for post CNC machining.

Well designed CNC program to guarantee the the parts precision.

Based on your order quantity to choose the “smart” facility/technics to save your cost.

Responsible OQC will 100% inspect the parts, specially all the key dimension.

No worry about function, always 100% test before shipping.

In House Surface Treatment

Custom Die Casting

Parts for Any Industry

We think we can help you with our experience

Medical

Automotive

Home Appliance

Power tool

LED

Electronic consumer

Pharmaceutical

Mechanical

How We Control Your Parts Quality

15年专注精密模具,聚沙成塔,敢于身先,一站式服务提效率保品质

- ISO9001:2008

- TS16949

- ISO14001:2015

- Density Testing

- ROHS

- Dimension Checking

- Chemical composition inspection

- Mechanical property test

- Insides defects inspection

- Cosmetic inspection

- Coating thickness test

- Saul spray test

- Surface smoothness inspection

- Color inspection

- Melting temperature monitoring

- Al chemical composition inspection

- Die casting equipment parameter monitoring

- FQI dimension

- FQI Cosmetic

- IPQC

- X-ray inspection of special parts of castings

Factory Certification

- Die Casting Benefits

- Die Casting Alloy Process

- Die Casting Process

- Die Casting Surface Treatment Guide