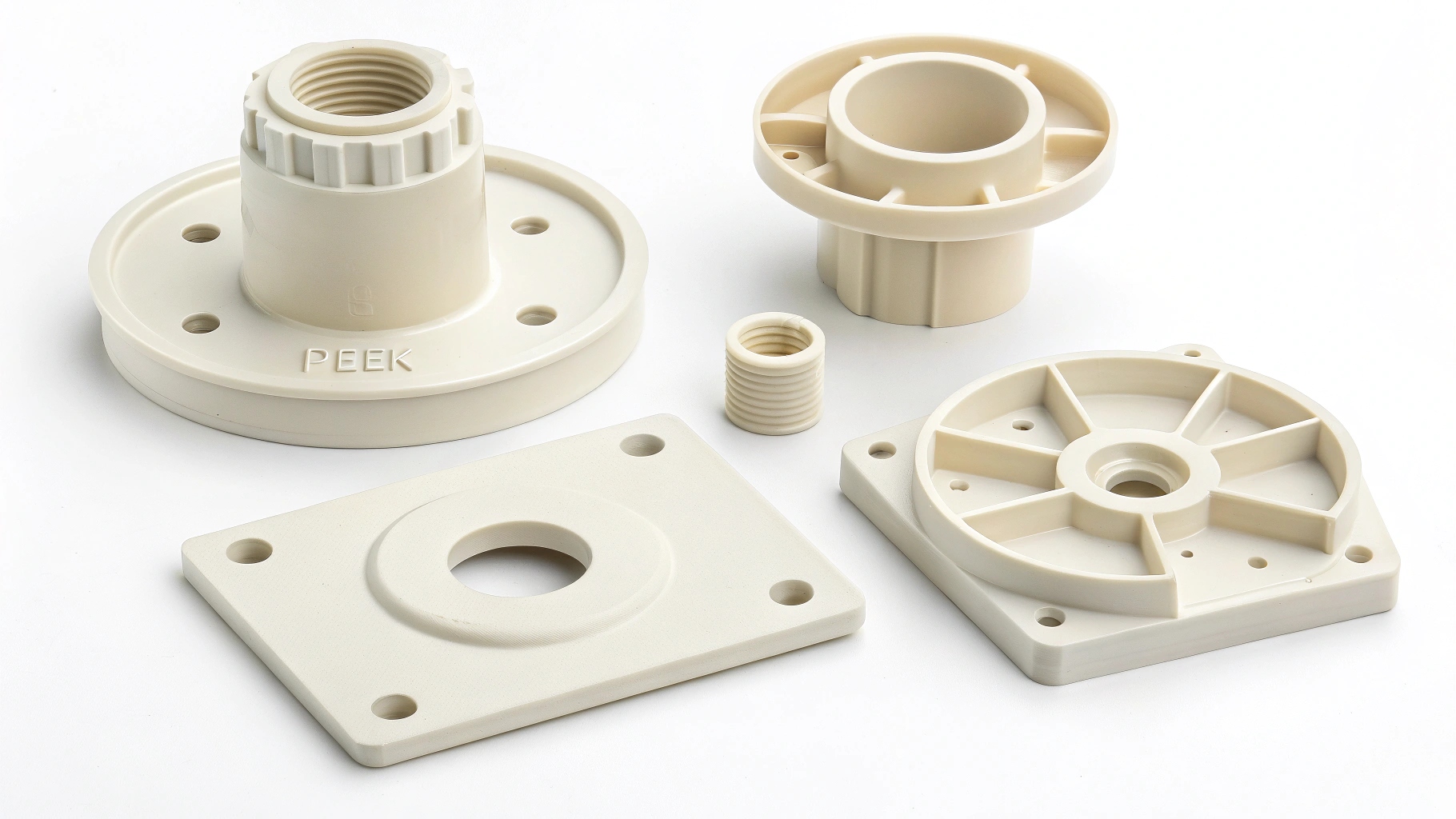

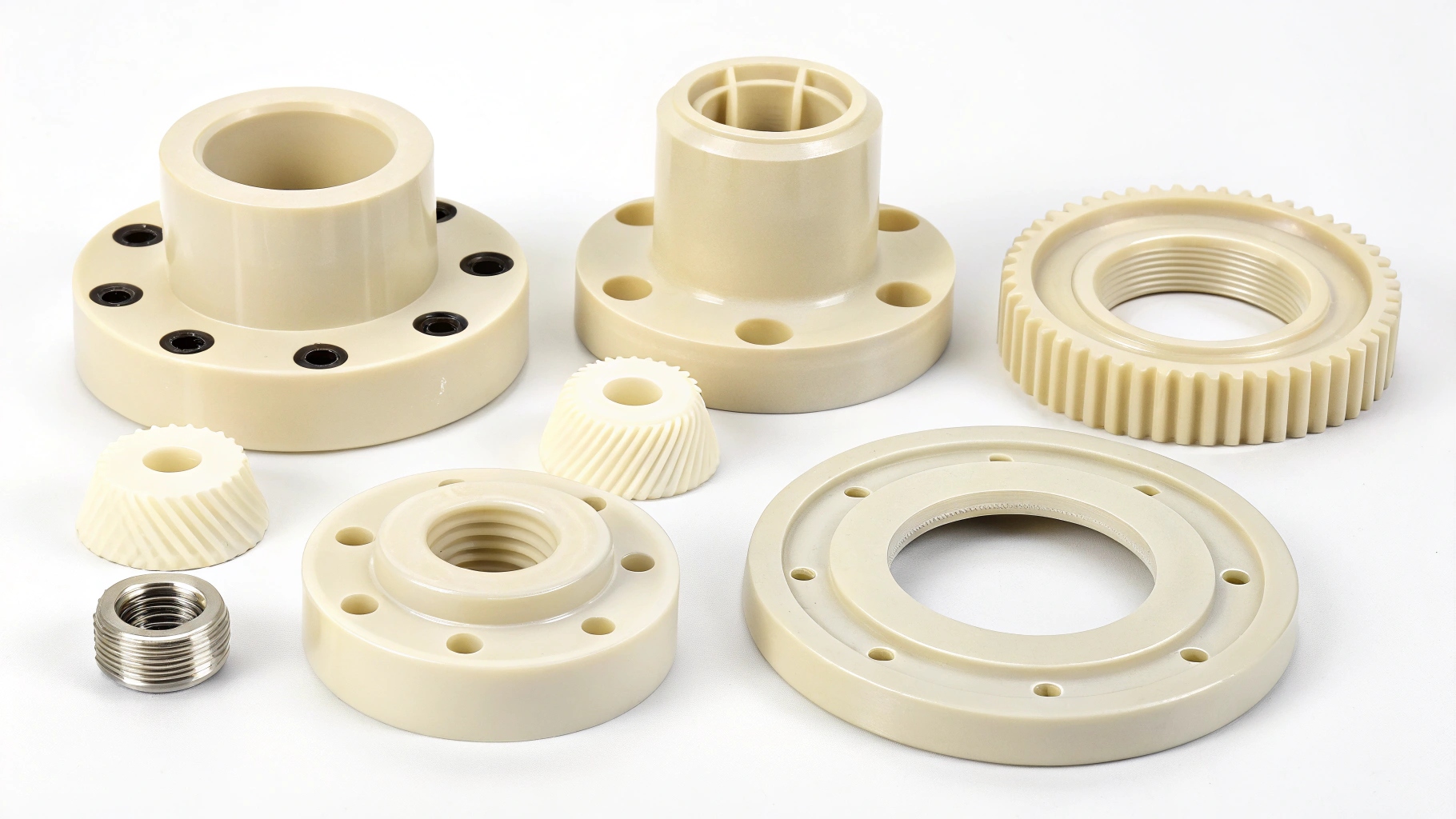

PEEK machining shapes a high-performance thermoplastic used in industries like aerospace, medical, and automotive. Renowned for its strength, chemical resistance, and heat tolerance, PEEK is machined with precision techniques to create durable, customized parts for critical applications.

If you’re curious about PEEK’s benefits and applications, let’s explore its unique properties and machining techniques in detail.

What is PEEK and its Properties?

PEEK (Polyether Ether Ketone) is a high-performance thermoplastic known for its exceptional strength, chemical resistance, and thermal stability up to 260°C. It is lightweight, biocompatible, and widely used in industries like aerospace, medical, and automotive for its durability and wear resistance.

Dive-Deeper: Why Choose PEEK for Your Projects?

PEEK stands apart due to its unique combination of properties, making it a top choice for demanding applications. Here’s a closer look:

Key Properties of PEEK

| Property | Description |

|---|---|

| Thermal Stability | Withstands temperatures up to 250°C. |

| Chemical Resistance 1 | Resistant to most chemicals and solvents. |

| Mechanical Strength | High strength-to-weight ratio. |

| Wear Resistance 2 | Low friction and excellent wear performance. |

Is PEEK Always the Best Choice?

While PEEK is impressive, it may not suit all applications. It’s essential to balance cost with specific project requirements.

- Advantages: High durability, biocompatibility, and lightweight properties.

- Limitations: Relatively high cost and specific machining requirements.

By understanding its strengths and limitations, you can decide if PEEK is the best fit for your project.

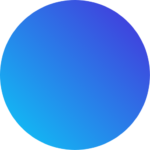

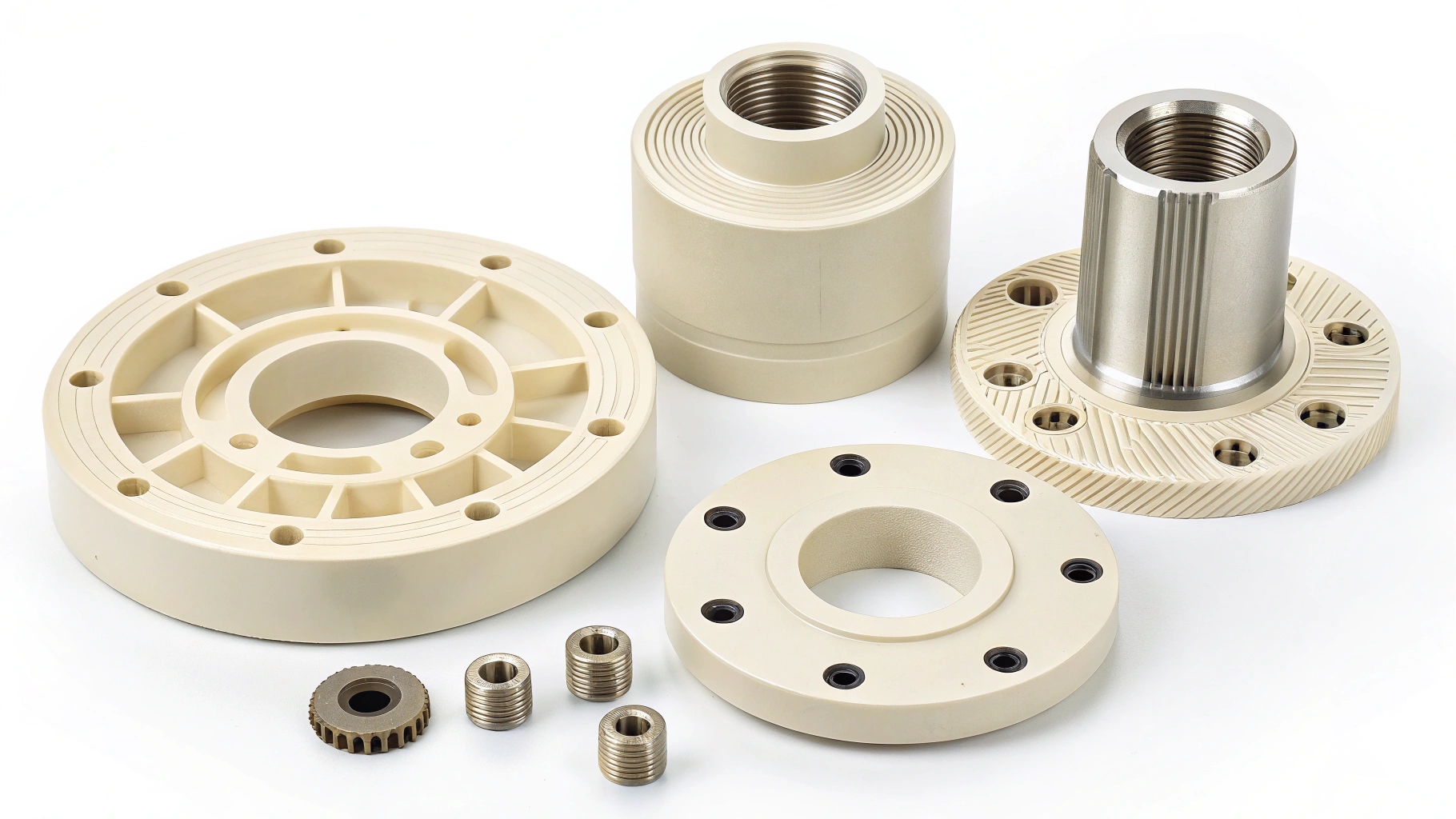

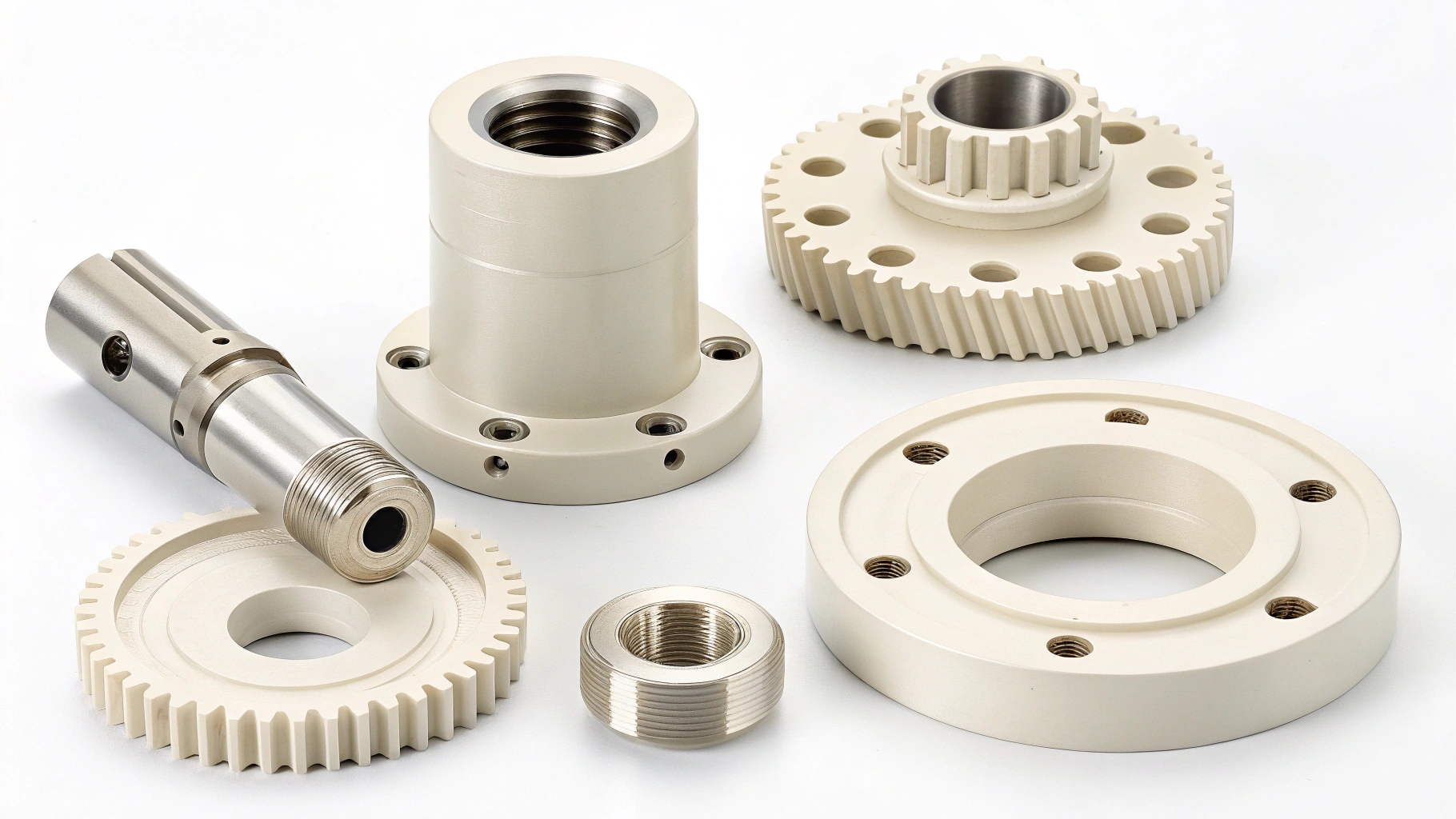

Applications of Machined PEEK Parts

PEEK is widely used in aerospace, medical, and automotive industries for making reliable, high-performance parts. Common applications include implants, surgical instruments, engine components, and seals, where its strength, chemical resistance, and heat tolerance are essential.

Dive-Deeper: Exploring PEEK’s Versatility in Industry

PEEK’s applications span various industries due to its reliability and performance. Here are some noteworthy examples:

Medical Devices 3

PEEK is biocompatible 4, making it ideal for:

- Implants: Long-term implantable devices like spinal cages.

- Surgical instruments: Tools that require precision and sterilization.

Aerospace

In aerospace, weight reduction and performance are critical. PEEK delivers:

- Lightweight components: Used in aircraft interiors.

- High-temperature resistance: Essential for engine parts.

Automotive

PEEK is a go-to material for enhancing vehicle efficiency:

- Engine components: Resistant to high temperatures and wear.

- Seals and gaskets: Durable and chemically resistant.

Why Is PEEK Preferred Over Alternatives?

PEEK often replaces metals and other plastics due to its superior strength and heat resistance. However, its cost demands careful consideration in budget-sensitive projects.

Techniques and Tips in PEEK Machining

PEEK machining requires precision, proper tool selection, and effective cooling. Use carbide or diamond-coated tools, manage feed rates to prevent overheating, and apply coolants to ensure high-quality, durable parts.

Dive-Deeper: Tips for Successful PEEK Machining

When machining PEEK, understanding its behavior is critical to achieving precision and efficiency. Here are some key techniques:

Preparation is Key

- Material Conditioning: Store PEEK in a controlled environment to prevent moisture absorption.

- Tool Selection: Use carbide or diamond-coated tools for precision.

Cutting Strategies 5

- Feed Rates: Maintain moderate feed rates to prevent overheating.

- Coolants: Apply coolants to minimize thermal expansion and tool wear.

Challenges in PEEK Machining

PEEK’s toughness can pose challenges:

| Challenge | Solution |

|---|---|

| High Cutting Temperatures | Use coolants to dissipate heat. |

| Burr Formation | Optimize cutting parameters and tooling. |

| Surface Finish Issues | Employ post-processing techniques. |

Advanced Techniques

For complex parts, CNC machining is a must. Multi-axis CNC machines enable:

- Precise cuts and tight tolerances.

- Production of intricate geometries.

Mastering these techniques ensures the production of high-quality PEEK parts for demanding applications.

Elue CNC Machining Services for PEEK Parts

What sets Elue apart when it comes to machining PEEK? Let’s discuss how we deliver excellence.

Elue specializes in precision CNC machining of PEEK, ensuring high-quality, customized components. Our services include tight tolerance cutting, surface finishing, and tailored solutions for industries like aerospace, medical, and automotive, backed by years of expertise and advanced equipment.

Dive-Deeper: Why Choose Elue for PEEK Machining?

Elue brings years of expertise and advanced technology to deliver exceptional results. Here’s what you can expect:

Comprehensive Capabilities

Our CNC machining services cover all your PEEK requirements:

- Precision Cutting: Tight tolerances and complex geometries.

- Surface Finishing: Polished, burr-free surfaces.

Customized Solutions

We collaborate closely with clients to deliver tailored solutions:

- Industry-specific expertise in medical, aerospace, and automotive.

- Prototyping and production services.

Quality Assurance

Elue is ISO9001/IATF16949 certified, ensuring top-notch quality. Our rigorous inspection processes guarantee consistency and reliability.

Why Work with Us?

| Feature | Benefit |

|---|---|

| Advanced Equipment | State-of-the-art CNC machines. |

| Experienced Team | Skilled engineers and machinists. |

| Global Reach | Serving clients in North America, Europe, and Australia. |

Partnering with Elue means you get reliable, high-quality PEEK parts, every time.

Conclusion

PEEK machining offers incredible potential for creating durable, high-performance components. Understanding its properties, applications, and machining techniques is crucial to success. At Elue, we combine expertise and technology to deliver exceptional PEEK solutions tailored to your needs.

-

Explains PEEK's resistance to chemicals, helping readers understand its suitability for harsh environments. ↩

-

Shows the wear and friction of PEEK composites. ↩

-

Shows why PEEK is great for medical applications. ↩

-

Explains the Biocompatibility of PEEK Polymers ↩

-

Gives full Machining Guidelines of PEEK. ↩