Identify problems early to avoid expensive rework and unhappy customers.

First Article Inspection (FAI) verifies that a part meets all design specifications before full production begins.

It’s a vital step for anyone serious about quality and consistency.

What Is First Article Inspection (FAI)?

Check the first part to avoid mass production errors.

First Article Inspection (FAI)1 is the initial verification of a part's compliance with engineering drawings and specifications.

FAI isn’t just a formality—it’s a necessary step in validating whether the production setup will consistently deliver the required results. During FAI, the first piece produced in a batch is inspected in full detail. It allows the machining team, engineers, and quality assurance staff to identify any discrepancies before proceeding with larger-scale production.

Key Elements Verified in FAI:

| Element | Why It Matters |

|---|---|

| Dimensional Accuracy2 | Ensures proper fit and function |

| Material Certification3 | Confirms correct raw materials |

| Surface Finish | Matches required texture or roughness |

| Functional Features | Guarantees usability in application |

| Tolerance Verification | Prevents later-stage assembly issues |

In our own shop, we’ve found that catching a missing chamfer or undercut during FAI has prevented days of rework. It’s much easier to fix one part than hundreds.

Why Is FAI Important in Custom Machining?

Every part matters when it's custom.

FAI reduces risks by validating processes and setups before mass production begins.

Unlike mass manufacturing, custom machining rarely deals with repeatability at scale. Each new job might involve new dimensions, materials, or tolerances. That’s why FAI becomes essential—to prove everything is dialed in before running the full batch.

Key Reasons to Conduct FAI:

- Early Detection of Errors: Avoid waste, rework, and late deliveries.

- Customer Confidence: Clients know their parts are verified before shipment.

- Internal Process Validation: Confirms machine setups, tooling, and programming are correct.

From my own experience, customers in the aerospace and medical industries often require formal FAI documentation. It's not optional—it's expected. Providing a clear, thorough FAI boosts our credibility and wins repeat business.

Key Steps in the First Article Inspection Process?

Follow a clear plan to make every inspection count.

FAI involves setup verification, first-part production, and thorough inspection against all specs.

Dive Deeper: The Full Process Breakdown

The FAI process can vary depending on the complexity of the part, but generally follows this flow:

FAI Workflow:

- Prepare Setup:

- Verify correct tools, fixtures, and CNC programs.

- Produce the First Part:

- Machine a single part under standard production conditions.

- Conduct Inspection:

- Measure all critical dimensions using calipers, micrometers, CMM, etc.

- Compare to Drawing:

- Match results with tolerances on the engineering drawing.

- Document Findings:

- Record results in an FAI report and attach supporting data.

- Get Customer Approval (if required):

- Some customers need to review and sign off before moving forward.

This process usually involves both machinists and QC inspectors. It encourages cross-checking and reduces errors from being overlooked.

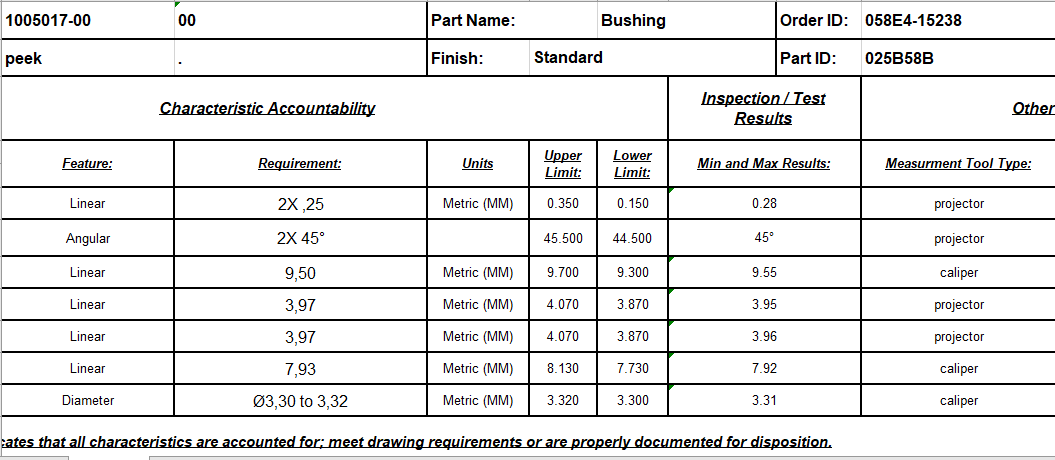

What Should Be Included in an FAI Report?

Don’t just say it’s OK—prove it.

An FAI report includes measurement results, material certification4s, and inspection tool details.

Dive Deeper: Creating a Clear and Useful FAI Report

FAI report5s vary by industry, but most follow a standard structure. This documentation proves that the part meets all specs before production scales up.

Common FAI Report Components:

| Section | Description |

|---|---|

| Part Information | Part number, revision, customer name |

| Drawing Requirements | All dimensions and tolerances |

| Measured Values | Actual measurements from first part |

| Pass/Fail Results | Whether each feature is within tolerance |

| Material Certification | Certificates proving correct materials were used |

| Tools and Equipment Used | Lists of calipers, CMMs, or other metrology tools |

| Operator and Inspector Info | Names and dates for accountability |

Providing complete and clean documentation builds trust with customers. It also creates a reference for future orders or audits.

How Does FAI Ensure Quality Control in Custom Machining?

You can’t control quality if you don’t inspect it.

FAI acts as the first line of defense against quality issues by validating process stability and repeatability.

Dive Deeper: Linking FAI to Long-Term Quality

When we machine parts, we aim for precision and repeatability. Without FAI, errors in machine setup, worn tooling, or programming mistakes could go unnoticed until it’s too late. FAI highlights these issues early.

How FAI Supports Quality:

- Baseline Data: Establishes reference for future inspections.

- Root Cause Analysis: Helps identify where things go wrong.

- Prevents Recalls: Reduces the risk of delivering out-of-spec parts.

- Improves Continuous Improvement: Trends from multiple FAIs can point out where process improvements are needed.

In our shop, we save FAI records for every job we run. If there’s ever a question later, we can trace back to the original inspection and verify what was done and why.

Common Challenges and Solutions in First Article Inspection?

It’s not always smooth—but it’s always worth it.

Common challenges include time constraints6, unclear specs, or inconsistent measuring tools7—but solutions exist.

FAI can become overwhelming when timelines are tight or drawings are unclear. But skipping it isn’t worth the risk. Instead, I’ve found that standardizing procedures and communication helps solve these issues.

Challenge and Fix Table:

| Challenge | How to Overcome |

|---|---|

| Time Pressure | Schedule inspection time in the production plan |

| Incomplete Drawings | Clarify with customer before machining begins |

| Measurement Inconsistencies | Calibrate tools regularly, use digital equipment |

| Untrained Staff | Offer FAI training for machinists8 and inspectors |

| Poor Documentation | Use FAI templates and checklists |

We once had a job delayed because an inspector missed a threaded hole callout. After that, we built our own inspection checklist template for all CNC projects—and it’s paid off again and again.

Conclusion

First Article Inspection ensures parts meet all specs before production. It boosts quality, reduces risk, and builds trust—especially in custom machining.

-

Understanding FAI is crucial for ensuring quality in manufacturing. Explore this link to learn more about its significance and processes. ↩

-

Dimensional accuracy is vital for product functionality. Discover why it matters and how to achieve it in production. ↩

-

Material certification ensures the right materials are used, impacting product quality. Learn more about its importance in manufacturing. ↩

-

Material certification is essential for compliance and quality assurance. Learn more about its importance in manufacturing processes. ↩

-

Understanding the components of an FAI report is crucial for ensuring quality control in manufacturing processes. Explore this link to gain insights into best practices. ↩

-

Understanding how to manage time constraints can significantly improve your FAI process and ensure quality outcomes. ↩

-

Exploring the impact of measurement tools on FAI can help you implement better practices and avoid costly mistakes. ↩

-

Investing in training resources can enhance your team's skills and improve the overall quality of inspections. ↩