Choosing the wrong lightweight metal can cost performance and safety.

Lightweight metals vary in strength, cost, corrosion resistance, and thermal properties—selecting the right one ensures optimal design and manufacturing results.

Each application has unique needs—let's find the ideal metal for yours.

What Are Lightweight Metals?

Weight reduction often improves performance, cost, and efficiency.

Lightweight metals are metals with low density used to reduce structural weight without compromising strength.

Dive Deeper: What Makes a Metal “Lightweight”?

Lightweight metals typically have a density under 5 g/cm³. These metals are essential in industries where performance depends on weight-to-strength ratio, corrosion resistance, or thermal conductivity.

Properties That Define Lightweight Metals

| Property | Explanation |

|---|---|

| Low Density | Lower weight per volume compared to traditional metals |

| High Specific Strength1 | Strong relative to their mass |

| Corrosion Resistance2 | Resists degradation in harsh environments |

| Good Machinability | Easily formed or machined |

Why It Matters in Machining

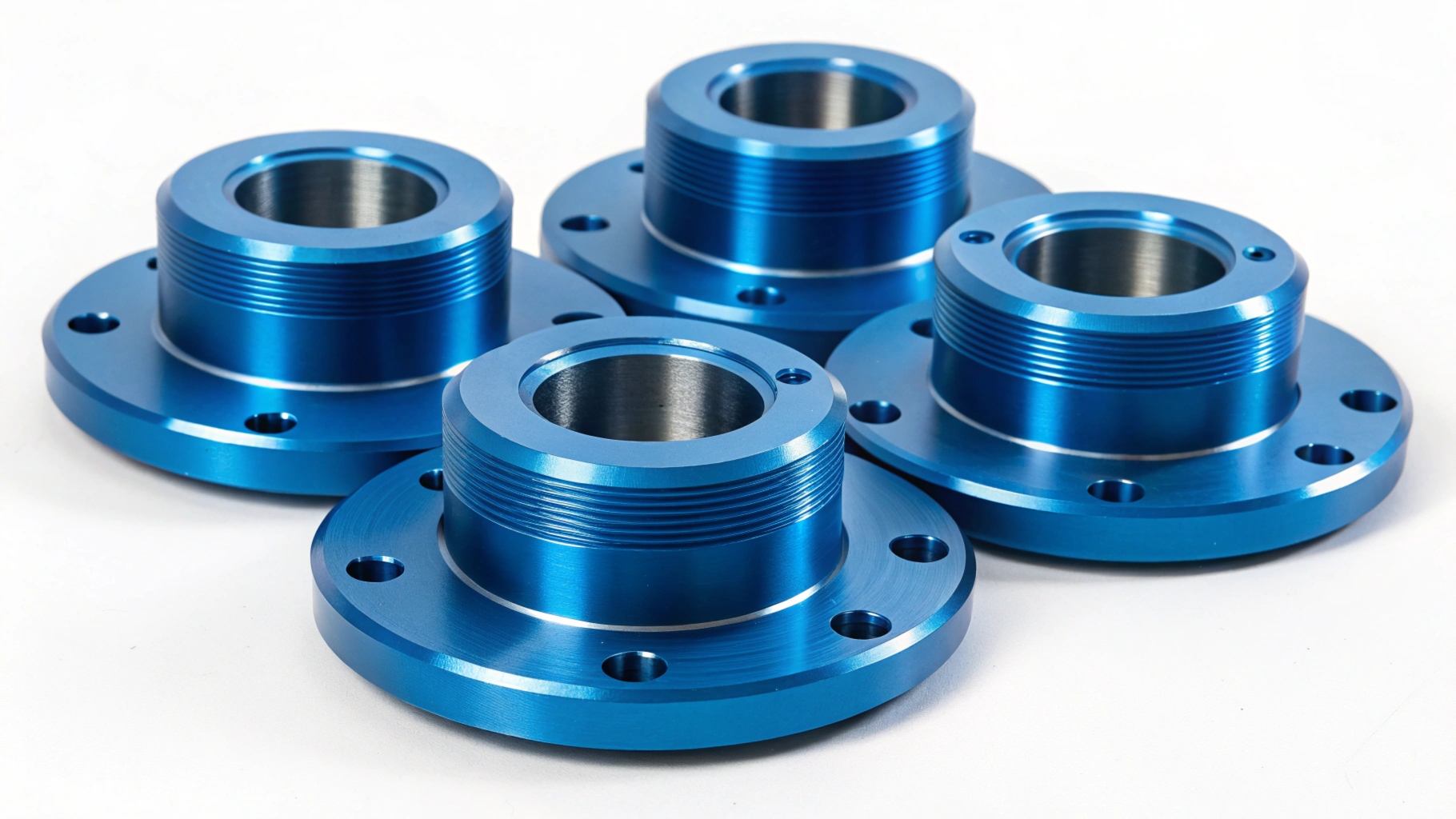

In my shop, when we machine lightweight metals like aluminum or titanium, we often achieve faster cycle times and lower material handling costs. These benefits compound during high-volume production or aerospace part machining.

Common Types of Lightweight Metals

Each lightweight metal has unique strengths and weaknesses.

The most used lightweight metals include aluminum, titanium3, magnesium, and beryllium—all offering different balances of weight, strength, and cost.

Dive Deeper: Comparing Lightweight Metal Options

Let’s break down the most commonly used lightweight metals and their characteristics.

Comparison Table

| Metal | Density (g/cm³) | Key Strengths | Common Uses |

|---|---|---|---|

| Aluminum | 2.7 | Low cost, corrosion-resistant, easy to machine | Aerospace, automotive, consumer products |

| Titanium | 4.5 | High strength-to-weight ratio, corrosion-resistant | Aerospace, medical implants |

| Magnesium | 1.7 | Lightest structural metal, great machinability | Automotive, electronics |

| Beryllium | 1.85 | Very stiff, high melting point | Aerospace, satellites |

Aluminum is our top choice for CNC machining when budget and turnaround are priorities. Titanium is unbeatable for performance, but it’s tougher to cut and more expensive. Magnesium machines beautifully but requires careful handling due to flammability.

Applications of Lightweight Metals in Various Industries

Demand for lightweight materials is growing across multiple sectors.

Lightweight metals are essential in aerospace, automotive, consumer electronics, sports equipment, and medical devices.

Dive Deeper: Real-World Applications by Industry

Aerospace

Aircraft components like brackets, fuselage panels, and turbine parts often use titanium or aluminum. Reducing aircraft weight saves millions in fuel.

Automotive

Magnesium alloys are gaining popularity in car seats, engine blocks, and gearboxes. Lighter vehicles improve fuel efficiency and reduce emissions.

Medical Devices

Titanium is biocompatible and corrosion-resistant, ideal for bone implants and dental hardware.

Consumer Products

Think of your laptop or phone—aluminum offers an ideal combination of lightness, heat dissipation, and appearance.

Sports and Recreation

From bicycle frames to golf clubs, high-performance equipment often relies on lightweight metals4 for agility and endurance.

Advantages and Limitations of Lightweight Metals

No material is perfect—trade-offs always exist.

While lightweight metals reduce mass and increase performance, they can be more expensive, harder to machine, or less durable in extreme conditions.

Dive Deeper: Pros and Cons Breakdown

Let’s look at what makes these metals attractive—and where they fall short.

Advantages

- Weight Savings: Especially in aerospace or transport, lighter structures mean better fuel economy.

- Improved Strength-to-Weight Ratios: Particularly with titanium and aluminum.

- Corrosion Resistance: Especially important in marine, chemical, or medical applications.

- Aesthetic Appeal: Aluminum and titanium often used in exposed consumer product surfaces.

Limitations

- Cost: Titanium and beryllium are significantly more expensive than steel or plastics.

- Machinability: Titanium and magnesium require specialized CNC tooling and safety precautions.

- Availability: Some alloys have longer lead times or tighter export controls.

Here in our factory, we weigh all these pros and cons before starting any CNC machining project. For example, if a customer prioritizes strength but has a strict weight budget, we lean toward titanium. If cost or speed matters more, aluminum becomes the go-to.

Conclusion

Choosing the right lightweight metal balances strength, cost, and machining ease—it shapes how your product performs.

-

Understanding high specific strength can help you choose the right materials for strength-to-weight applications. ↩

-

Learn why corrosion resistance is vital for material longevity and performance in various environments. ↩

-

Learn about titanium's biocompatibility and strength, making it perfect for medical applications like implants and devices. ↩

-

Explore the advantages of lightweight metals in various industries and how they enhance performance and efficiency. ↩