CNC machining requires precision, repeatability, and efficiency. Without the right fixtures, achieving consistent quality can be a challenge.

CNC fixtures are essential components that secure workpieces during machining, ensuring accuracy, repeatability, and production efficiency across various applications.

Choosing the right fixture can significantly impact machining efficiency and product quality. In this guide, I'll walk you through everything you need to know about CNC fixtures.

What Are CNC Fixtures?

CNC fixtures securely hold workpieces during machining to ensure accuracy, repeatability, and efficiency by preventing movement and reducing setup time.

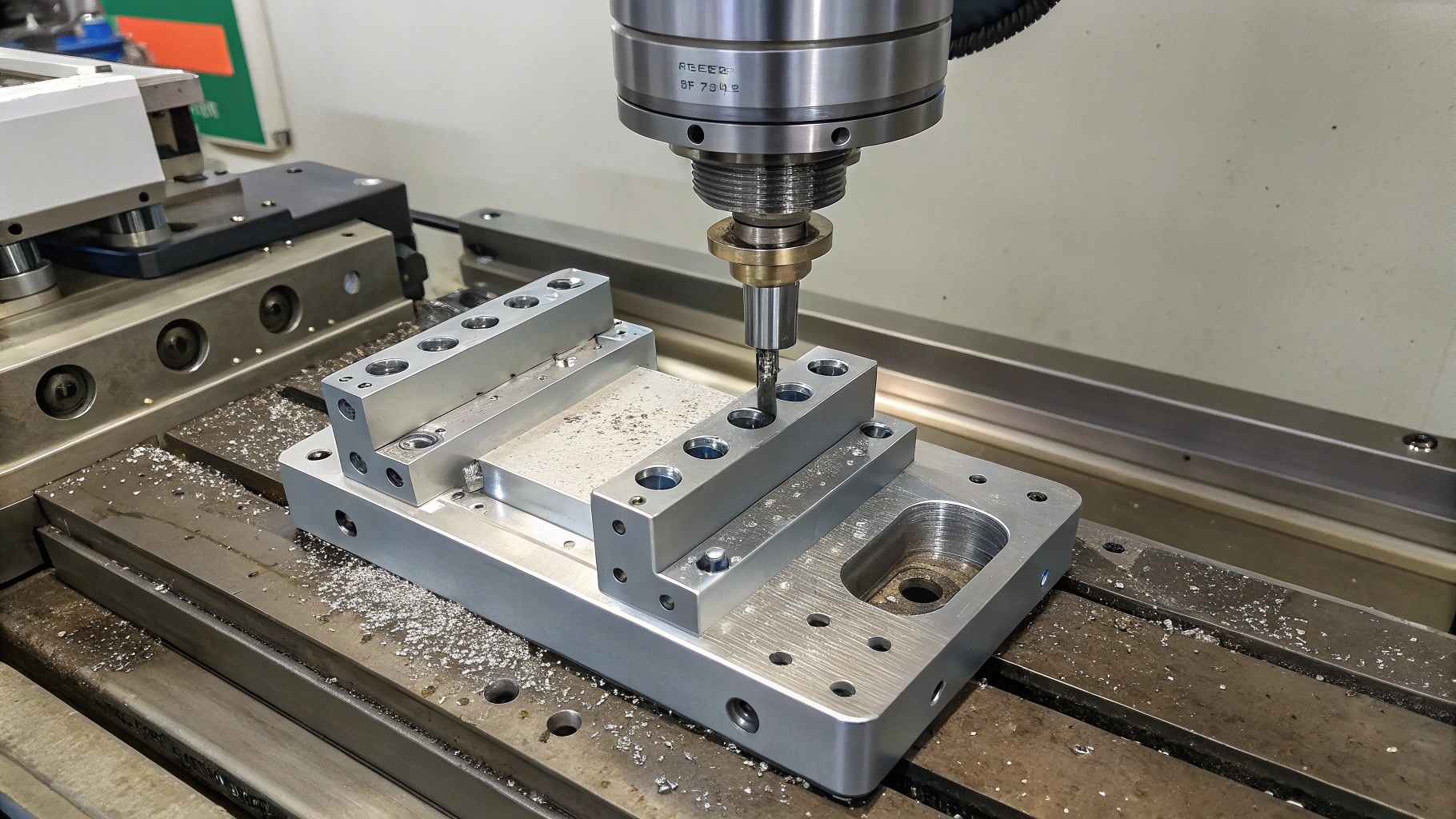

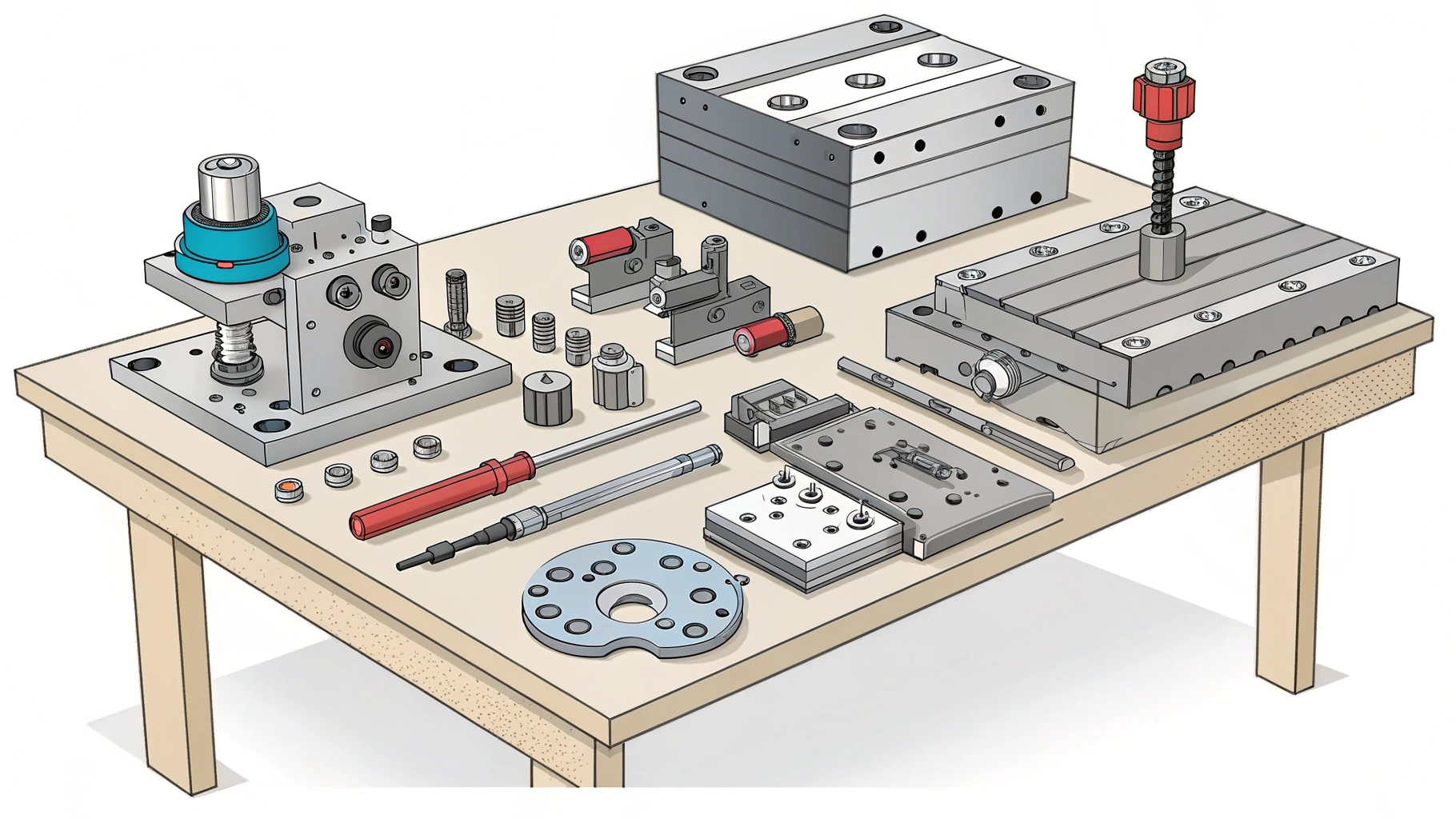

different-types-of-cnc-fixtures

Dive Deeper: Understanding the Role of CNC Fixtures

CNC fixtures play a crucial role in the manufacturing process by:

- Ensuring Stability: They prevent unwanted movement and vibration1, which can lead to inaccuracies.

- Reducing Setup Time: Fixtures minimize the time required to align and secure the workpiece, enhancing efficiency.

- Improving Safety: Secure fixtures reduce the risk of accidents caused by shifting parts during machining.

- Enhancing Consistency: Fixtures enable mass production with consistent dimensions and quality2.

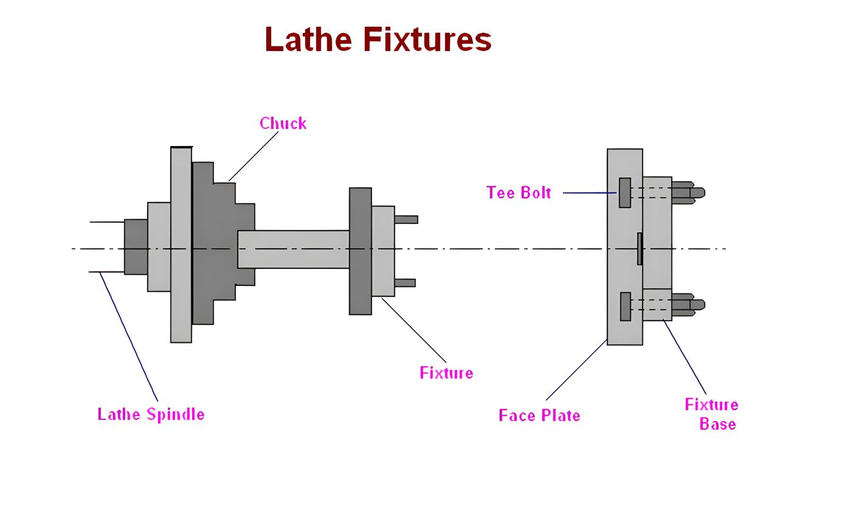

Components of a CNC Fixture

A typical CNC fixture consists of:

| Component | Function |

|---|---|

| Base Plate | Provides a stable foundation |

| Clamping System | Holds the workpiece securely |

| Locating Pins | Ensure precise positioning |

| Support Elements | Prevent deformation during machining |

Understanding these components helps in selecting the right fixture for specific applications.

Types of CNC Fixtures

CNC fixtures include modular, dedicated, vacuum, and hydraulic/pneumatic types, each designed to securely hold workpieces and improve machining accuracy and efficiency.

Dive Deeper: Common Types of CNC Fixtures

-

Modular Fixtures

- Composed of interchangeable components.

- Ideal for low to medium production volumes.

- Flexibility for different workpiece shapes.

-

Dedicated Fixtures

- Designed for specific workpieces.

- Ensures high precision but lacks flexibility.

- Suitable for high-volume production.

-

Vacuum Fixtures

- Use suction to hold lightweight materials.

- Ideal for delicate parts such as thin plastics.

- Reduces the need for mechanical clamps.

-

Hydraulic/Pneumatic Fixtures

- Utilize fluid or air pressure to secure parts.

- Automates clamping, reducing setup time.

- Suitable for large-scale operations.

Each fixture type has its advantages and trade-offs. Choosing the right one depends on the complexity of the part and production goals.

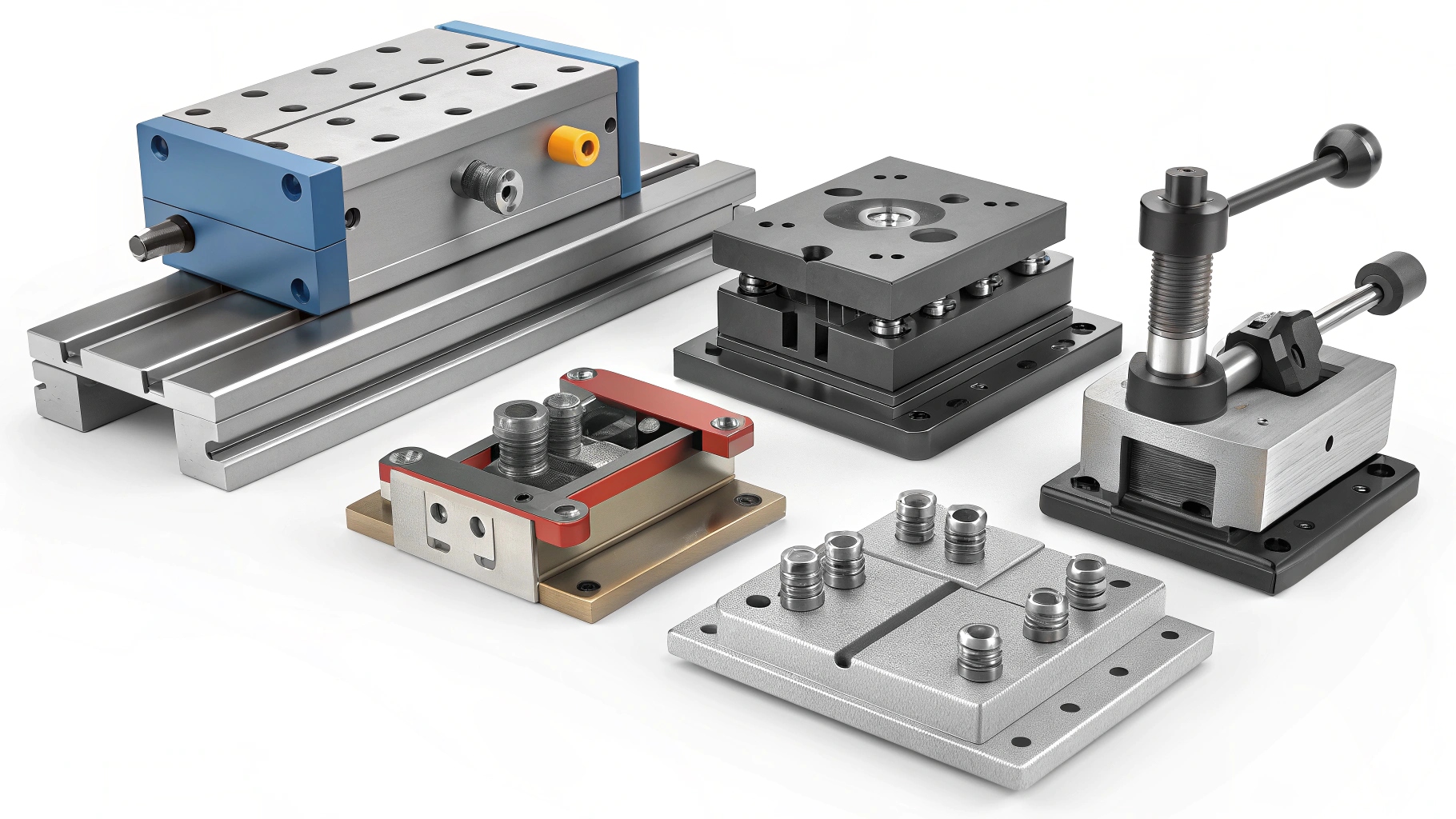

Benefits of Using CNC Fixtures

CNC fixtures enhance machining by improving accuracy, efficiency, and safety, while reducing errors, setup time, and material waste.

CNC machining fixtures

Dive Deeper: Key Advantages of CNC Fixtures

-

Increased Precision

Fixtures provide consistent positioning, ensuring precise cuts and dimensions, which reduces rework and scrap rates. -

Enhanced Productivity

Proper fixturing streamlines operations, allowing operators to focus on machining rather than setup. -

Cost Savings

By minimizing material waste and machining errors, fixtures contribute to overall cost reduction in manufacturing processes. -

Operator Safety

Secure workpieces prevent accidents, ensuring compliance with safety standards. -

Scalability

CNC fixtures enable rapid production scaling without compromising quality.

Investing in high-quality fixtures pays off in terms of efficiency, accuracy, and overall shop profitability.

Key Considerations When Designing Fixtures

Important factors in designing CNC fixtures include workpiece material, tolerances, machining forces, and accessibility to ensure accuracy and efficiency.

Fixture design

Fixture design

Dive Deeper: Factors to Consider in Fixture Design

-

Workpiece Material

Different materials require different clamping forces and support structures to prevent deformation. -

Tolerance Requirements

The fixture must hold the workpiece in a way that maintains tight tolerances throughout the machining process. -

Machining Forces

Cutting forces can impact fixture stability. The design should ensure resistance to such forces to avoid inaccuracies. -

Accessibility

The fixture should allow easy access for machining tools without interference. -

Repeatability

Fixtures should be designed for quick repeatable setups to maintain production efficiency. -

Cost vs. Benefit

Balancing fixture complexity with production needs ensures optimal cost-efficiency.

Considering these factors ensures that fixtures perform effectively across various production scenarios.

Common Applications of CNC Fixtures

CNC fixtures are used in aerospace, automotive, medical, and electronics industries to enhance precision and efficiency.

CNC fixture applications

CNC fixture applications

Dive Deeper: Key Industry Applications

-

Aerospace Industry

- Fixtures support the production of complex components with tight tolerances3.

- Materials like titanium and aluminum require special fixturing to prevent deformation.

-

Automotive Industry

- High-volume production of engine components and structural parts.

- Dedicated fixtures ensure repeatability and quality assurance.

-

Medical Equipment Manufacturing

- Precision is critical for surgical tools and implants.

- Fixtures help maintain strict regulatory standards.

-

Electronics Industry

- CNC fixtures assist in machining delicate components such as enclosures and connectors.

- Vacuum fixtures are often used for thin and lightweight parts.

By understanding the application requirements of CNC fixtures, manufacturers can optimize their machining processes for specific industry needs.

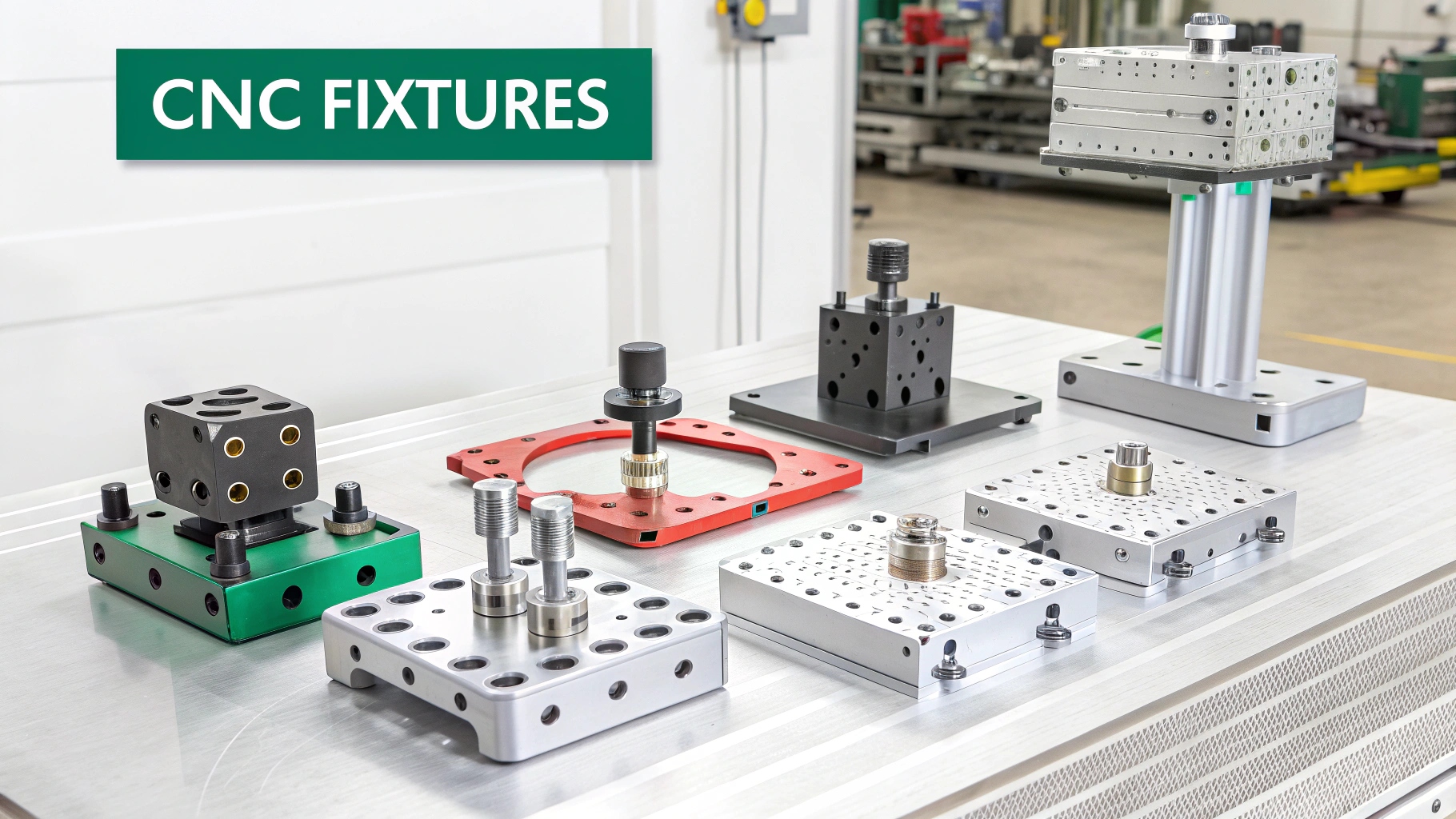

Shanghai Elue: Your Reliable CNC Machine Shop for Custom Fixtures

Choosing the right partner for your CNC fixturing needs can make all the difference in achieving optimal results.

Shanghai Elue specializes in providing high-precision custom CNC fixtures tailored to your manufacturing requirements, backed by years of experience and ISO-certified processes.

Shanghai Elue CNC shop

Shanghai Elue CNC shop

Dive Deeper: Why Choose Shanghai Elue for CNC Fixtures?

-

Expertise and Experience

With over a decade of experience, we understand the unique challenges of CNC machining and fixture design. -

State-of-the-Art Equipment

Our facility is equipped with advanced CNC machines4, allowing us to produce fixtures with tight tolerances. -

Customized Solutions

We work closely with clients to design fixtures that meet their exact specifications and production goals. -

Quality Assurance

Our ISO9001/IATF16949 certifications5 guarantee that each fixture meets the highest quality standards. -

Global Reach

Serving clients across North America, Europe, and Australia, we offer reliable solutions with fast turnaround times.

If you're looking for precision, reliability, and excellent customer support, Shanghai Elue is your go-to partner for CNC fixtures.

Conclusion

CNC fixtures play a critical role in achieving precision, efficiency, and repeatability in manufacturing. Choosing the right fixture and design ensures optimal machining performance.

-

This resource will explain the mechanisms behind CNC fixtures' ability to maintain stability, crucial for high-quality machining outcomes. ↩

-

Discover how CNC fixtures are essential for achieving uniformity in mass production, a key factor for industries relying on precision. ↩

-

This resource will explain the critical role of CNC fixtures in achieving the high precision required for aerospace components, ensuring safety and performance. ↩

-

Discover the cutting-edge advancements in CNC machine technology that enable the production of fixtures with tight tolerances and superior quality. ↩

-

This link provides insights into the importance of ISO9001/IATF16949 certifications in ensuring the highest quality standards in CNC machining. ↩