Boring is a key process in machining that creates precise holes. It’s used to enhance the size, roundness, and finish of existing holes.

Boring allows manufacturers to improve the dimensions and finish of a hole, ensuring tight tolerances and high-quality finishes.

If you’re working on parts that need precise holes, read on to understand why boring might be the best solution.

What is Boring in Machining?

Boring is the process of enlarging or refining an existing hole with high precision. Unlike drilling, which creates a hole from scratch, boring is used to improve the diameter, smoothness, and alignment of an already existing hole.

Boring allows for very tight tolerances1 and smooth finishes, making it ideal for high-precision applications.

Dive Deeper: The Basics of the Boring Process and Its Advantages

Boring is essentially an enhancement process. After drilling, you may need to refine the hole further. Here's why boring is so essential:

1. Precision

Boring ensures that holes are precisely aligned and sized according to specifications. It’s often used when high tolerances are required, especially in aerospace, automotive, and medical parts.

2. Surface Finish

The process also improves the surface finish2 of the hole. Boring machines can leave a much smoother finish than drilling or reaming, which is critical in parts where friction or sealing is important.

3. Improved Accuracy

Boring provides more control over the diameter of a hole. If the hole needs to fit another component with a very tight fit, boring can achieve the necessary precision.

| Boring Advantage | Impact on Part Quality |

|---|---|

| Precision | Tight tolerances for high-performance parts |

| Surface Finish | Smooth hole for sealing or less friction |

| Diameter Control | Accurate hole size for press fits or bearings |

In our shop, we’ve used boring to refine parts for the automotive industry where precision alignment for bearing housing is non-negotiable. The difference in accuracy is substantial compared to initial drilling.

Types of Boring Processes?

There’s more than one way to perform boring, and the method depends on the requirements of the job.

Different boring methods offer distinct benefits, like improving hole size or finishing the hole’s surface.

Dive Deeper: Exploring Common Boring Techniques

Depending on your design needs, the type of boring process you choose can have a big impact on efficiency and precision.

1. Straight Boring

This is the most basic type of boring. It’s used to enlarge or finish holes in parts that have a straight geometry. This process is commonly used when a simple hole needs to be adjusted in diameter and aligned precisely.

2. Radial Boring3

Radial boring is used to create holes at specific angles, and it’s typically seen in more complex machining operations. The tool moves along a circular arc while the part rotates.

3. Back Boring4

Back boring is used to create a hole that begins at the back or opposite side of the part. This is commonly used for deep holes where the entry is not easily accessible.

4. Deep Hole Boring5

When machining deep holes with long lengths, deep hole boring is required. Specialized tools allow for precision in deep and narrow holes, especially for components like engine blocks.

| Boring Type | Ideal Use Case | Common Tooling |

|---|---|---|

| Straight Boring | Enlarging or finishing simple holes | Boring bars, drill bits |

| Radial Boring | Angled holes or specific geometric features | Radial boring heads |

| Back Boring | Accessing deep or difficult holes | Back boring bars, extended tooling |

| Deep Hole Boring | Machining long, narrow holes | Specialized deep hole boring tools |

In our factory, we use deep hole boring for automotive engine parts, where long, precise holes are needed for fuel injection systems. These processes demand advanced tooling to ensure accuracy throughout the depth.

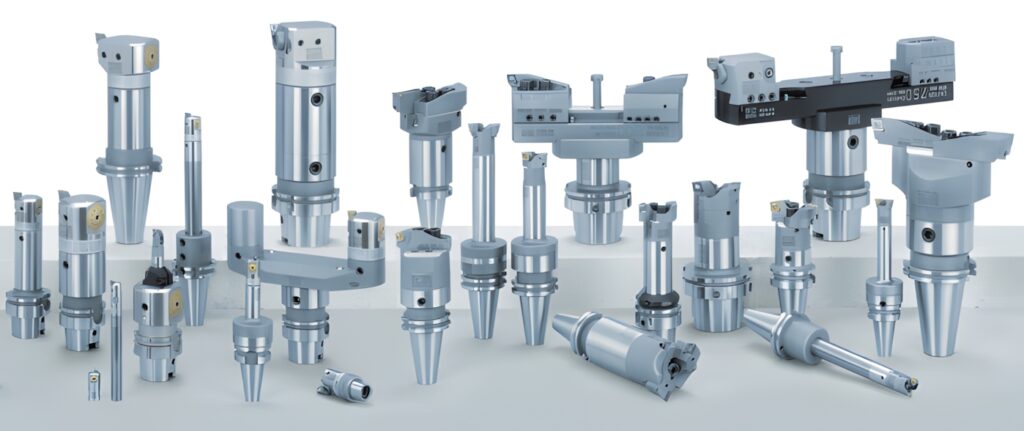

Tools and Machines Used for Boring?

Boring requires specific tools and machinery to ensure that holes are enlarged and finished with precision.

The right combination of tools and machines is crucial to achieving the desired results in the boring process.

Dive Deeper: The Equipment That Makes Boring Possible

Boring tools and machines have evolved over time to provide more accuracy and versatility. Let’s explore the essential tools and machines used in boring operations:

1. Boring Bars6

Boring bars are the primary tools used in the boring process. They are long, slender tools that fit into a machine to enlarge the hole. They come in different sizes and materials, with carbide-tipped boring bars being quite common for harder materials.

2. Boring Heads

A boring head holds the boring bar and provides fine adjustments for precise control. This tool allows machinists to make minute changes to the hole’s diameter during operation.

3. Vertical Boring Machines7

These machines are used to machine large parts like flanges, rings, and housings. A vertical boring machine allows for a high degree of precision while handling large, heavy workpieces.

4. Horizontal Boring Mills8

Horizontal boring mills are typically used for heavy-duty and high-precision work. The workpiece is held in place on a horizontal axis, and the tool moves along the length of the piece.

| Equipment Type | Description | Application |

|---|---|---|

| Boring Bars | Long tools used to cut the hole larger | Standard boring operations |

| Boring Heads | Holds boring bars and allows fine adjustments | Precision diameter control |

| Vertical Boring Machines | Ideal for large parts like flanges or rings | Heavy-duty, high-precision parts |

| Horizontal Boring Mills | For deep holes in heavy, large parts | Deep hole machining, large workpieces |

We recently worked on machining large compressor housings for an industrial client. The vertical boring machine gave us the necessary precision while managing the heavy parts, ensuring that the bore alignment met tight specifications.

Applications of Boring in Manufacturing?

Boring is used in several industries for high-precision machining.

From aerospace to automotive, boring helps create components that require tight tolerances and smooth finishes.

Dive Deeper: Exploring Industries That Rely on Boring

Boring’s applications vary widely based on industry needs. Let’s take a closer look at some of the primary uses:

1. Aerospace

Aerospace parts, such as engine components, require high precision. Boring is used to machine the intricate holes in turbine blades, engine casings, and other critical components where tight tolerances are essential.

2. Automotive

In automotive manufacturing, boring is used to create precise holes in engine blocks, gearboxes, and transmission parts. These holes need to accommodate bearings or other components with perfect fits.

3. Medical Equipment

Boring is commonly used for creating precise holes in medical equipment parts, such as syringes, implants, and surgical instruments, where the accuracy of the hole is critical for functionality and safety.

4. Heavy Machinery

Boring is used in heavy machinery for parts like bearings and bushings. These components often require a combination of large holes and high tolerance to operate under extreme conditions.

| Industry | Boring Application | Key Characteristics |

|---|---|---|

| Aerospace | Engine components, turbine blades | Extremely tight tolerances and surface finish |

| Automotive | Engine blocks, gearboxes, transmission parts | Precision for bearing fit and functionality |

| Medical Equipment | Surgical instruments, implants | High precision for safety and performance |

| Heavy Machinery | Bearings, bushings, large housings | Ability to machine large, heavy components |

We often work with aerospace clients who require ultra-precise boring for turbine engine components. One of our recent projects involved boring turbine casings for a leading jet engine manufacturer, where accuracy was critical to ensure the part could withstand high operational pressures.

Challenges and Best Practices in Boring?

While boring is highly effective, it comes with some challenges that need careful attention.

Understanding common challenges and best practices helps improve efficiency and product quality during the boring process.

Dive Deeper: Overcoming Boring Challenges

The main challenges in boring often arise from tool wear, vibration, and material characteristics. Let’s look at some best practices to overcome these obstacles:

1. Tool Wear

Boring tools experience wear over time, especially in hard materials. Using high-quality carbide tools, along with proper lubrication, can help extend tool life and maintain precision.

2. Vibration

Excessive vibration can affect the quality of the bore. Ensuring the workpiece is securely fixed and selecting the right feed rates can help minimize vibration.

3. Chip Removal

Efficient chip removal is essential to avoid material buildup and maintain precision. Using coolant and maintaining an optimal cutting speed ensures that chips are cleared quickly.

4. Material Considerations

Different materials behave differently under the cutting tool. For instance, harder metals like stainless steel require slower speeds and more coolant than softer materials like aluminum.

| Challenge | Solution | Best Practice |

|---|---|---|

| Tool Wear | Use carbide or coated tools, regular maintenance | High-quality tooling, optimal cutting speeds |

| Vibration | Secure workpieces, adjust feed rates | Use vibration-damping tools or techniques |

| Chip Removal | Use coolant and high-speed rotation | Ensure proper cutting parameters |

| Material Behavior | Adjust feeds, speeds, and coolant use | Follow material-specific guidelines |

In our shop, we use advanced coolant systems to manage chip removal and keep the tooling cool, which has improved our boring efficiency by 15%.

Conclusion

Boring is an essential machining process for achieving high precision and smooth finishes in various industries. By using the right tools, processes, and practices, manufacturers can produce parts that meet tight tolerances and perform effectively in critical applications.

-

Understanding tight tolerances is essential for ensuring quality in manufacturing, especially in critical industries like aerospace and automotive. ↩

-

This link will help you grasp why surface finish matters in machining, impacting performance and longevity of parts. ↩

-

Discover how Radial Boring can enhance your machining operations by allowing for angled holes and complex geometries, boosting overall efficiency. ↩

-

Learn about Back Boring techniques and their applications in accessing hard-to-reach areas, essential for deep hole machining. ↩

-

Explore this link to understand advanced techniques and tools for achieving precision in deep hole boring, crucial for automotive applications. ↩

-

Explore this link to understand the various types of boring bars and their applications in precision machining. ↩

-

Learn about the functionality and benefits of vertical boring machines for large-scale machining tasks. ↩

-

Discover the role of horizontal boring mills in achieving high precision for heavy-duty machining operations. ↩