Struggling to achieve perfection in acrylic machining? Learn how to maximize its potential.

Acrylic is a versatile material with diverse applications, but its machining requires careful precision and expertise.

Explore the unique properties of acrylic and how to optimize its machining process.

What is Acrylic? An Overview of Its Properties and Uses

Acrylic offers a balance of strength, clarity, and versatility, making it ideal for many industries.

Acrylic (PMMA) is a lightweight, transparent, and durable thermoplastic. It offers excellent optical clarity, weather resistance, and impact strength. Commonly used in windows, signage, displays, and automotive parts, acrylic is easy to machine and ideal for both indoor and outdoor applications.

Key Properties of Acrylic

Acrylic stands out for its combination of qualities, including:

| Property | Description |

|---|---|

| Optical Clarity | Up to 92% light transmission, similar to glass. |

| Weather Resistance 1 | Exceptional durability in outdoor conditions. |

| Lightweight | Half the weight of glass but equally strong. |

| Machinability | Suitable for CNC machining and customization. |

Common Uses of Acrylic

Acrylic’s properties make it useful across multiple industries, such as:

- Automotive: Headlight covers and instrument panels.

- Medical Equipment: Display screens and protective shields.

- Aerospace: Transparent components and lightweight parts.

Its adaptability to precision machining elevates its value in complex designs.

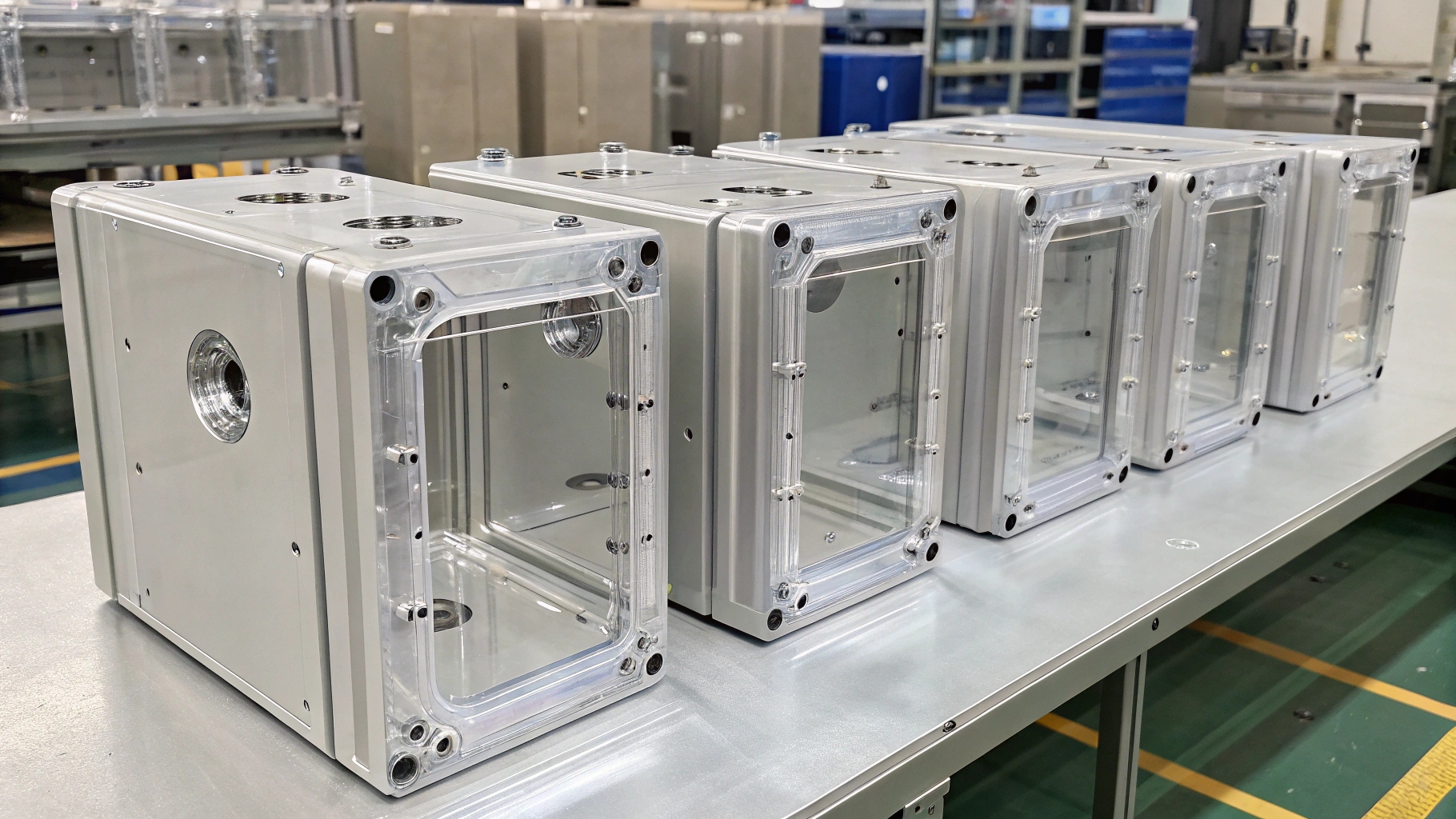

Why Acrylic is a Popular Choice for CNC Machining?

Acrylic is widely used in CNC machining due to its exceptional clarity, durability, and ease of machining. It delivers smooth, polished surfaces for high-precision parts like lenses, displays, and signage. Lightweight, weather-resistant, and versatile, acrylic is ideal for both indoor and outdoor applications.

Dive Deeper: Key Benefits of Machining Acrylic

Acrylic's popularity stems from its ability to meet stringent requirements:

1. Precision and Versatility

CNC machining delivers tight tolerances, crucial for industries demanding accuracy. Acrylic can be milled, drilled, and shaped with minimal risk of cracking when handled properly.

2. Enhanced Aesthetic Appeal

Polished acrylic achieves a crystal-clear finish, ideal for high-visibility parts like displays or lenses. Unlike other materials, it combines transparency with durability.

| Benefit | Acrylic Compared to Alternatives |

|---|---|

| Machining Precision | Superior to glass2, easier than polycarbonate. |

| Finish Quality | High optical clarity after polishing. |

| Cost Effectiveness | More affordable than glass in large projects. |

These attributes justify its widespread use across technical and artistic applications.

Tips for Achieving Precision and Clarity in Acrylic Machining

Struggling with cracks or cloudiness? These tips will help you master acrylic machining.

Use proper tools, moderate speeds, and coolants to prevent chipping and overheating. Opt for single-flute tools and secure the material. Finish with polishing for smooth, transparent surfaces.

Dive Deeper: Steps for Better Acrylic Machining

1. Choose the Right Tools 3

Using sharp, carbide-tipped tools prevents heat buildup and material stress.

2. Adjust Speeds and Feeds

Optimal machining speed avoids melting or cracking. CNC machines should operate at slower speeds to minimize heat.

3. Use Coolants

Coolants or air jets dissipate heat effectively during cutting or drilling, maintaining clarity.

4. Polishing for Perfection

Post-machining polishing 4 removes micro-scratches and enhances clarity.

| Machining Parameter | Recommended Value |

|---|---|

| Cutting Speed | 3,000 – 4,500 RPM |

| Feed Rate | 0.1 – 0.5 mm/revolution |

| Coolant Type | Water-based or air cooling |

Attention to detail ensures precise, high-quality results for every machined acrylic piece.

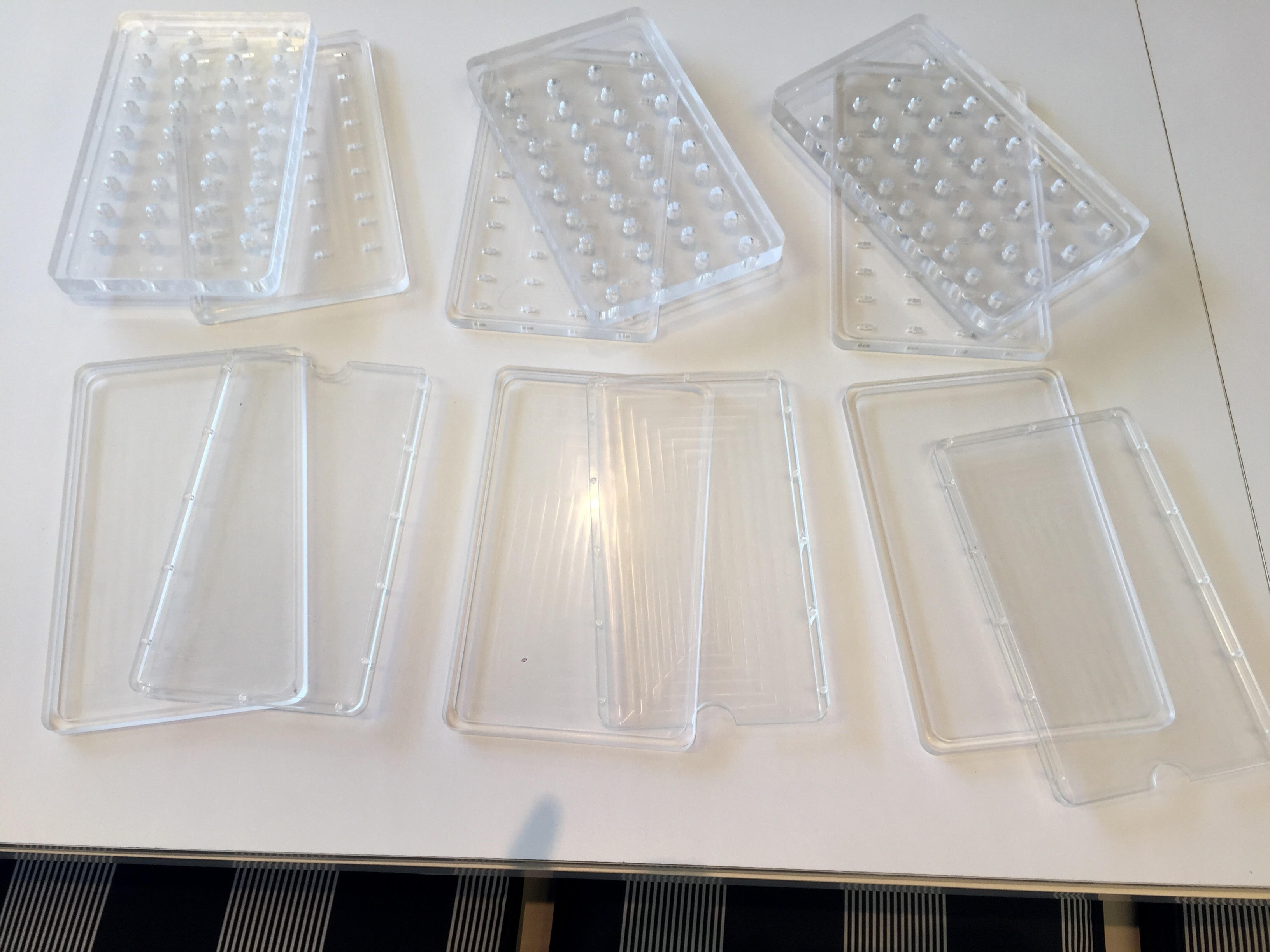

Common Applications of Machined Acrylic Components

Where does acrylic machining shine? Discover its role in innovation.

Display cases, signage, lenses, medical enclosures, automotive light covers, and architectural panels. Acrylic’s clarity, durability, and machinability suit diverse industries.

Dive Deeper: Industry Applications

1. Medical Equipment

Machined acrylic is used for its transparency and biocompatibility. Examples include:

- Protective shields and barriers.

- Diagnostic equipment housings.

- Light-guiding components.

2. Consumer Electronics

Acrylic enhances the visual appeal and functionality of:

- Smartphone stands.

- TV displays.

- Transparent keyboards.

3. Automotive and Aerospace

In vehicles, acrylic’s light weight and strength are valued for components like:

| Application Area | Example Components |

|---|---|

| Automotive | Headlight lenses, dashboards |

| Aerospace | Windshields, lightweight panels |

Its ability to withstand extreme conditions reinforces its importance in these sectors.

Challenges in Acrylic Machining and How to Overcome Them

Machining acrylic is not without its challenges. Learn how to tackle common issues.

Prevent chipping by using sharp tools and low feed rates. Avoid overheating with coolants and proper speeds. Polish rough edges, handle carefully to avoid scratches, and minimize stress with preheating.

Dive Deeper: Solving Acrylic Machining Problems

1. Heat Management

Excessive heat can cause melting and deformation. Solutions include:

- Using sharp tools to minimize friction.

- Applying coolants or air jets consistently.

2. Avoiding Stress Cracks

Stress cracks 5 occur when material is handled improperly. Tips to prevent this:

- Ensure gradual transitions in designs.

- Avoid high-pressure clamping during machining.

3. Tool Wear and Tear

Blunt tools create rough edges and micro-fractures. Regularly replacing or sharpening tools is essential.

Troubleshooting Acrylic Machining Issues

| Issue | Cause | Solution |

|---|---|---|

| Cloudy Finish | Improper polishing | Use finer polishing compound |

| Cracks During Cutting | Excessive feed rate | Reduce feed rate |

| Warping | Heat buildup | Use coolant consistently |

Addressing these challenges ensures smooth and flawless acrylic machining results.

Conclusion

Acrylic machining combines creativity and precision. With the right techniques and tools, you can unlock its full potential for various industries.

-

To provide evidence for acrylic's durability in outdoor applications and its weather-resistant properties. ↩

-

To highlight acrylic's superior optical clarity and aesthetic benefits compared to glass. ↩

-

To identify the types of tools ideal for acrylic machining and why they help prevent cracks and cloudiness. ↩

-

To guide readers on how to achieve a smooth, transparent finish after machining. ↩

-

To educate on stress-related issues during machining and how to prevent them. ↩