EDM machining is a non-contact manufacturing process that uses electrical discharges (sparks) to remove material from a workpiece. This process is particularly effective for machining hard metals and creating intricate geometries that are difficult to achieve with traditional methods.

EDM is ideal for producing complex shapes, fine details, and sharp corners, making it a preferred solution for high-precision applications in aerospace, automotive, medical, and mold-making industries.

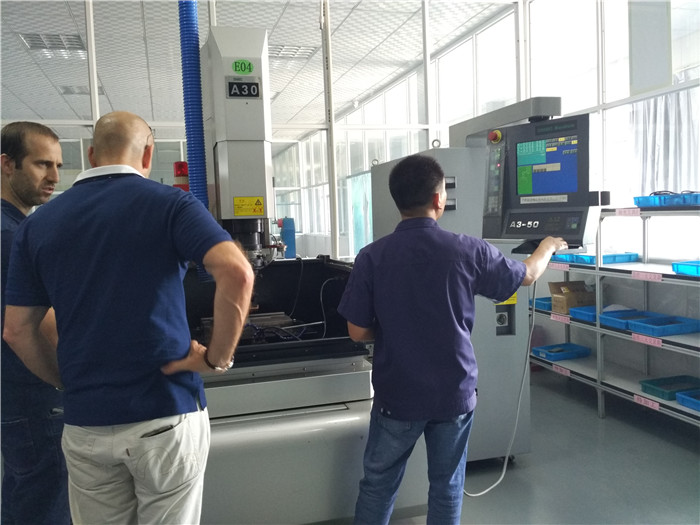

Elue Industry specializes in delivering high-quality EDM machined components with unparalleled precision and flexibility. Our skilled engineers utilize state-of-the-art EDM machines, including wire EDM and sinker EDM, to create complex parts with exceptional surface finishes and tight tolerances.

Whether you need delicate parts with micro-features or robust tooling components, Elue Industry is equipped to handle projects of any complexity.

At Elue Industry, we prioritize precision and reliability in every project. Our comprehensive quality control measures ensure that every EDM-machined part meets the highest standards of accuracy and performance.

Inspection Process

Each part undergoes detailed inspections to verify:

Dimensional Accuracy: Measurements to ensure tight tolerances for critical applications.

Surface Finish: Smooth and uniform finishes tailored to functional and aesthetic requirements.

Geometric Precision: Verification of intricate details, sharp edges, and complex shapes.

Get the latest updates via email. Don’t miss it. Any time you may unsubscribe.