Aluminum corrodes fast without coatings. Choosing the right one prevents costly failures.

There are many aluminum coatings available, and each has strengths and weaknesses for specific uses.

The wrong choice ruins performance. The right one improves durability, appearance, and cost-effectiveness.

Different Types of Coatings for Aluminum?

Aluminum is lightweight and strong, but it’s reactive. Coatings are essential to protect it.

Popular aluminum coatings include anodizing, powder coating1, painting, electroplating, and chemical films2.

An Overview of Common Coatings

Let’s look deeper into the coating types commonly used in manufacturing and architecture.

| Coating Type | Process Type | Durability | Appearance | Typical Use |

|---|---|---|---|---|

| Anodizing | Electrochemical | High | Matte/Satin | Aerospace, electronics |

| Powder Coating | Dry Spray | Very High | Glossy | Consumer goods, outdoor equipment |

| Painting | Liquid Spray | Moderate | Customizable | Appliances, automotive panels |

| Chemical Conversion | Chemical Bath | Low to Medium | Yellow/Iridescent | Military, aviation parts |

Each of these serves a different purpose. For example, anodizing changes the surface itself, while painting only adds a protective outer layer. Chemical films offer only mild protection but are ideal where electrical conductivity is still required.

How Each Coating Method Works?

Knowing how a coating is applied helps in deciding its suitability for your project.

Each coating type uses a unique process that affects cost, speed, and adhesion.

A Look Inside Coating Application Methods

Let me explain how each method is applied:

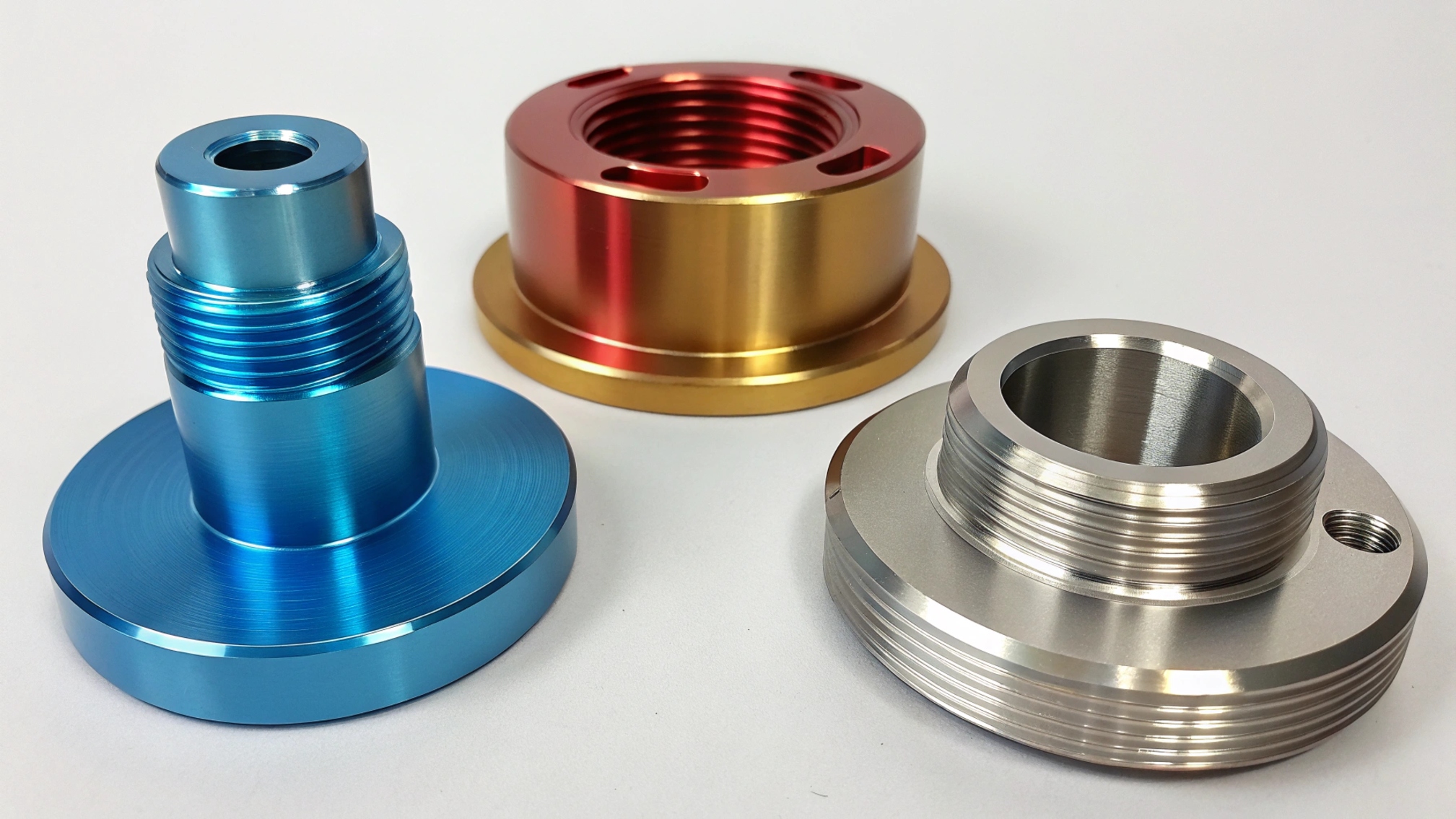

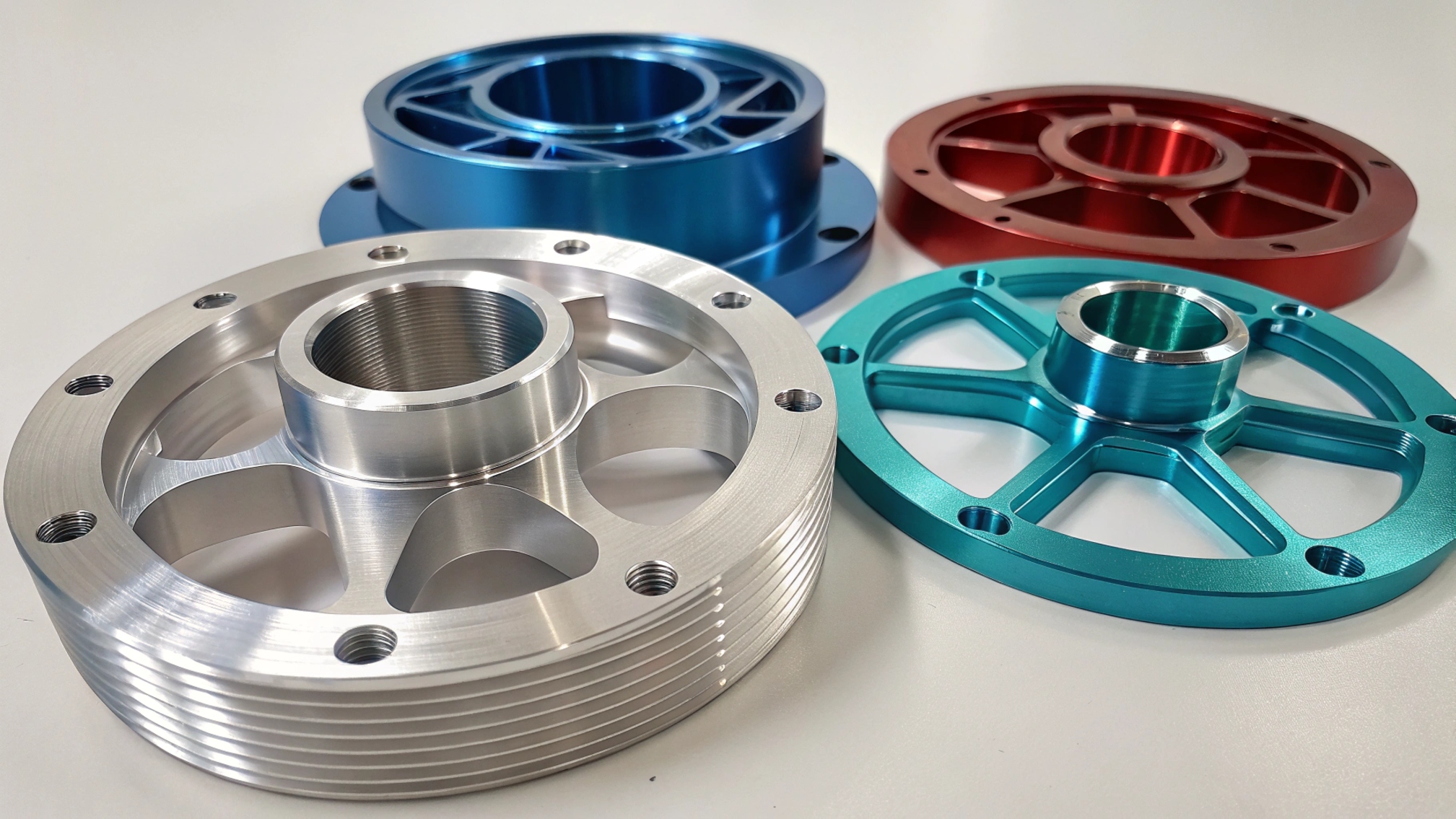

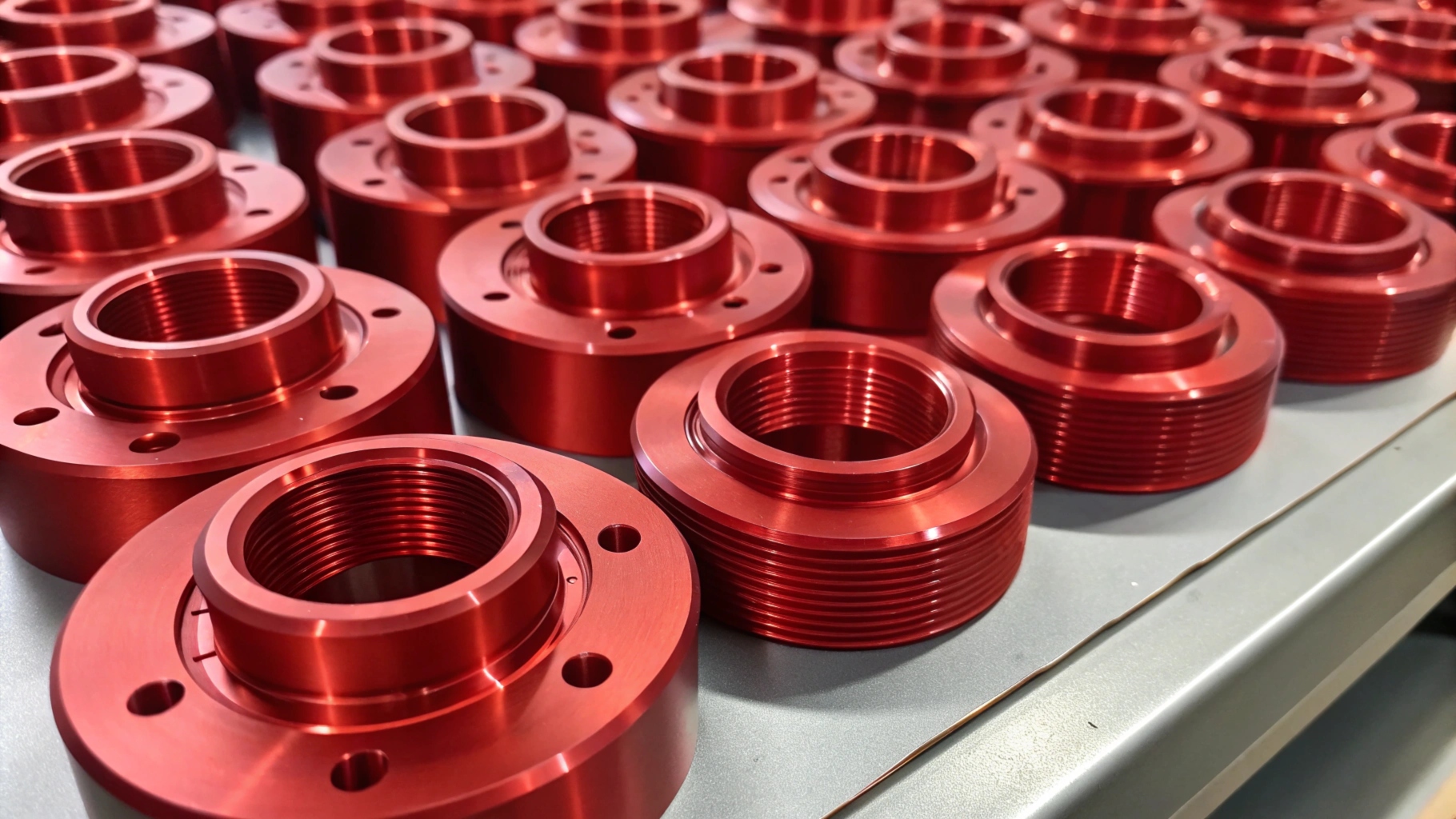

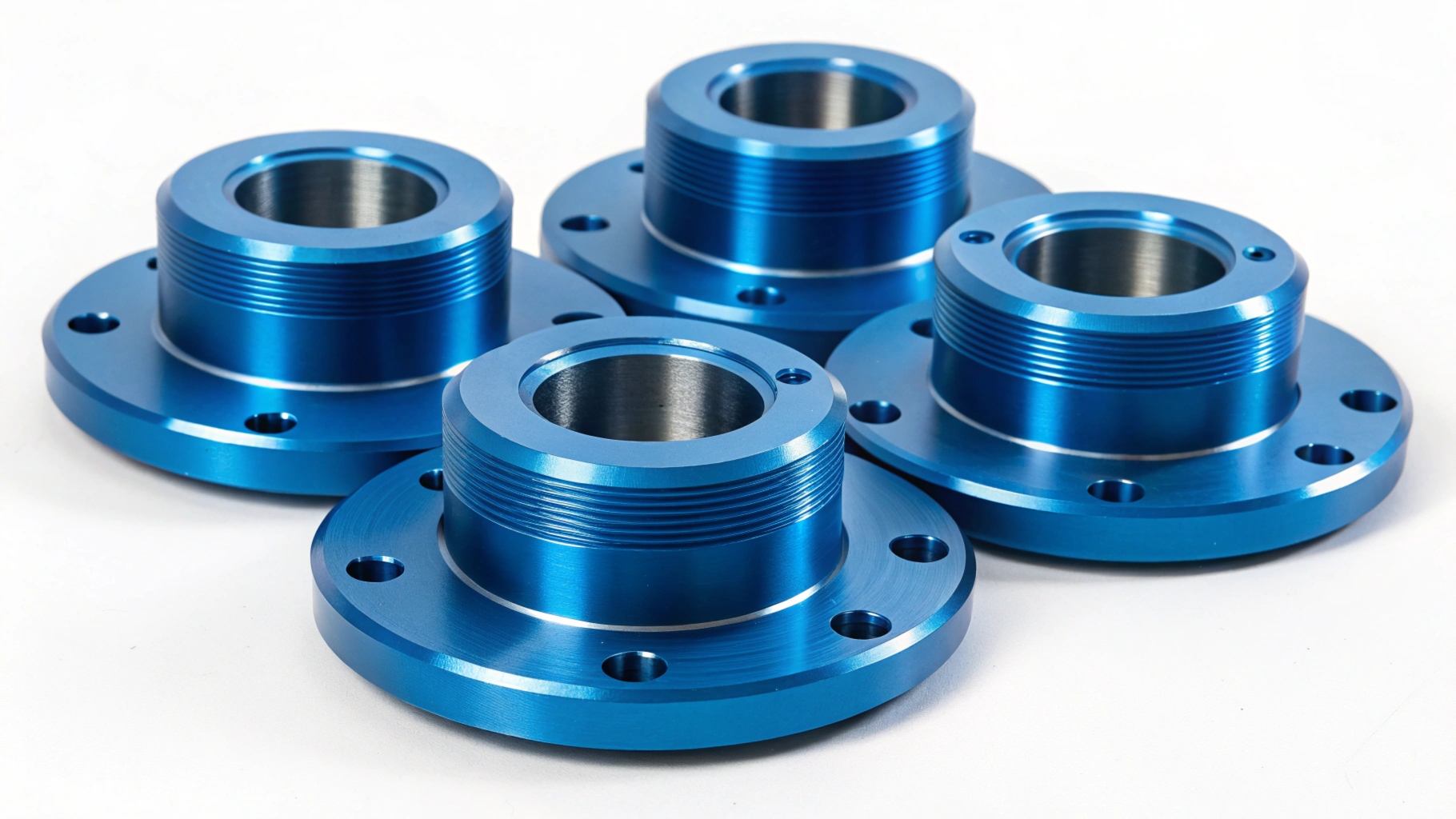

Anodizing

This electrochemical process thickens the oxide layer on aluminum. It requires immersion in an acid electrolyte and the application of electricity. The result is a tough, non-conductive surface.

Powder Coating

Powder particles are sprayed using electrostatic guns. Then the part is baked in an oven. The powder melts, flows, and hardens into a solid film. It’s fast, clean, and environmentally friendly.

Painting

Liquid paint is applied with spray guns or brushes. After drying or curing, it forms a film on the metal. Paint allows infinite color choices but may chip over time.

Beadblasting

Bead blasting uses fine glass beads propelled at high speed to clean or finish a surface. It creates a smooth, matte texture without removing much material. This method improves aesthetics and hides machining marks but offers little corrosion resistance on its own.

Chemical Conversion Coating3 (e.g. Alodine)

This method uses chemicals that react with the aluminum surface to form a thin, corrosion-resistant film. It’s fast and cheap, ideal for low-impact parts that need electrical conductivity.

Process Comparison Table

| Feature | Anodizing | Powder Coating | Painting | Electroplating | Chemical Film |

|---|---|---|---|---|---|

| Heat Required | Yes | Yes | Maybe | No | No |

| Electrical Conductivity | No | No | No | Yes | Yes |

| Custom Colors Available | Limited | Yes | Yes | Yes | No |

| Thickness Control | Good | Moderate | Moderate | Good | Poor |

| Surface Hardness | High | High | Low | High | Low |

Understanding these differences helps me select coatings based on needs, not just appearance.

Advantages and Disadvantages of Each Coating?

No coating is perfect. Each one trades off cost, appearance, durability, and complexity.

Choosing a coating requires balancing strengths and weaknesses for your specific goals.

Comparing the Pros and Cons

Here’s my hands-on insight after years in the machining industry.

Anodizing

- Pros: High hardness, corrosion-resistant, doesn’t peel.

- Cons: Limited color options, non-conductive, can crack under stress.

Powder Coating

- Pros: Attractive, tough, customizable.

- Cons: Thickness might affect tight tolerances, needs oven curing.

Painting

- Pros: Cost-effective, easy to touch up, unlimited colors.

- Cons: Chips over time, not very durable in tough environments.

Beadblasting

- Pros: Creates a uniform matte finish, removes surface imperfections, non-abrasive to base material.

- Cons: Offers no corrosion protection, surface may stain or oxidize if not coated afterward.

Chemical Films4

- Pros: Simple process, conductive, good base for painting.

- Cons: Lower durability, poor aesthetics.

Real-World Implications

For aerospace parts, anodizing is common because of its wear resistance. But for consumer items like bicycle frames, powder coating works better for color and cost. For connectors or housings where conductivity matters, chemical films are usually preferred.

Factors to Consider When Selecting a Finish?

Even the best coating can fail if it's wrong for the application.

Think about function, aesthetics, cost, and environment when picking a finish.

What I Ask Before Choosing a Coating

Here are the questions I ask every time:

What’s the part’s function?

- Moving parts need hard finishes like anodizing.

- Structural parts exposed to weather might benefit from powder coating.

- Decorative parts may require electroplating.

What’s the operating environment?

- High UV exposure? Use UV-stable coatings.

- Corrosive settings? Pick thicker or multi-layer finishes.

Do you need electrical conductivity?

- Avoid anodizing and powder coating if conduction is needed.

- Go for conversion coatings instead.

What are the cost and production limits?

- For high-volume, low-budget items, painting or conversion coating may be more viable.

- For premium parts, anodizing or plating may justify the investment.

Practical Comparison Table

| Factor | Best Coating Type |

|---|---|

| Low Cost | Painting, Chemical Film |

| Long-Term Durability | Powder Coating, Anodizing |

| Aesthetic Flexibility | Painting, Electroplating |

| Tight Tolerance Parts | Anodizing, Chemical Film |

| Electrical Conductivity | Chemical Film, Electroplating |

When clients come to me with custom projects, I don’t push a “best” option. Instead, I recommend based on the part’s role, usage, and desired life span.

Common Applications of Aluminum Coatings?

Aluminum coatings are everywhere—from airplanes to smartphones.

Different industries rely on specific coatings based on performance and regulatory needs.

Industry Use Cases

Aerospace

- Preferred Coatings: Anodizing5 and Alodine.

- Reason: Lightweight, corrosion-resistant, and meets aviation standards.

Automotive

- Preferred Coatings: Powder coating6, painting.

- Reason: Durable under sunlight, aesthetic appeal, easy mass production.

Electronics

- Preferred Coatings: Chemical conversion.

- Reason: Maintains electrical grounding paths.

Consumer Products

- Preferred Coatings: Powder coating, painting, sometimes plating.

- Reason: Colors and surface feel matter more than pure functionality.

Medical Equipment

- Preferred Coatings: Anodizing.

- Reason: Hard surface, easy to sterilize, biocompatible.

Application Table

| Industry | Coating Used | Key Benefit |

|---|---|---|

| Aerospace | Anodizing, Alodine | Weight-saving, corrosion control |

| Automotive | Powder Coating | Weather resistance, color choice |

| Consumer Goods | Painting, Plating | Brand appeal, cost control |

| Electronics | Chemical Film | Conductivity |

| Medical Devices | Anodizing | Biocompatibility |

I’ve worked with clients across these fields. Often, they’re unsure what coating fits their case. My job is to guide them—choosing wrongly might delay production or increase failure rates.

Conclusion

Aluminum coatings aren’t one-size-fits-all. Knowing how they work and what they offer helps choose the right one for each part and industry.

-

Discover the benefits of powder coating, including durability and finish quality, which make it a popular choice for many applications. ↩

-

Learn about chemical films, their protective qualities, and why they are essential in specific applications like military and aviation. ↩

-

Learn about chemical conversion coating to see how it enhances aluminum's corrosion resistance while maintaining conductivity. ↩

-

Learn about chemical films and their applications, including their conductivity and aesthetic limitations, to better understand their use in various industries. ↩

-

Explore the advantages of anodizing in aerospace for weight-saving and corrosion control, crucial for aircraft performance. ↩

-

Discover how powder coating enhances durability and aesthetics in automotive manufacturing, making it a popular choice. ↩