Choosing the right material for CNC machining can be overwhelming. The wrong choice could compromise your project.

To select the ideal material for a CNC part, consider factors like material properties 1, application requirements, cost constraints, and environmental impacts to ensure optimal performance and functionality.

But how do you navigate the myriad of options available? Let's delve deeper into making the best material choice for your CNC project.

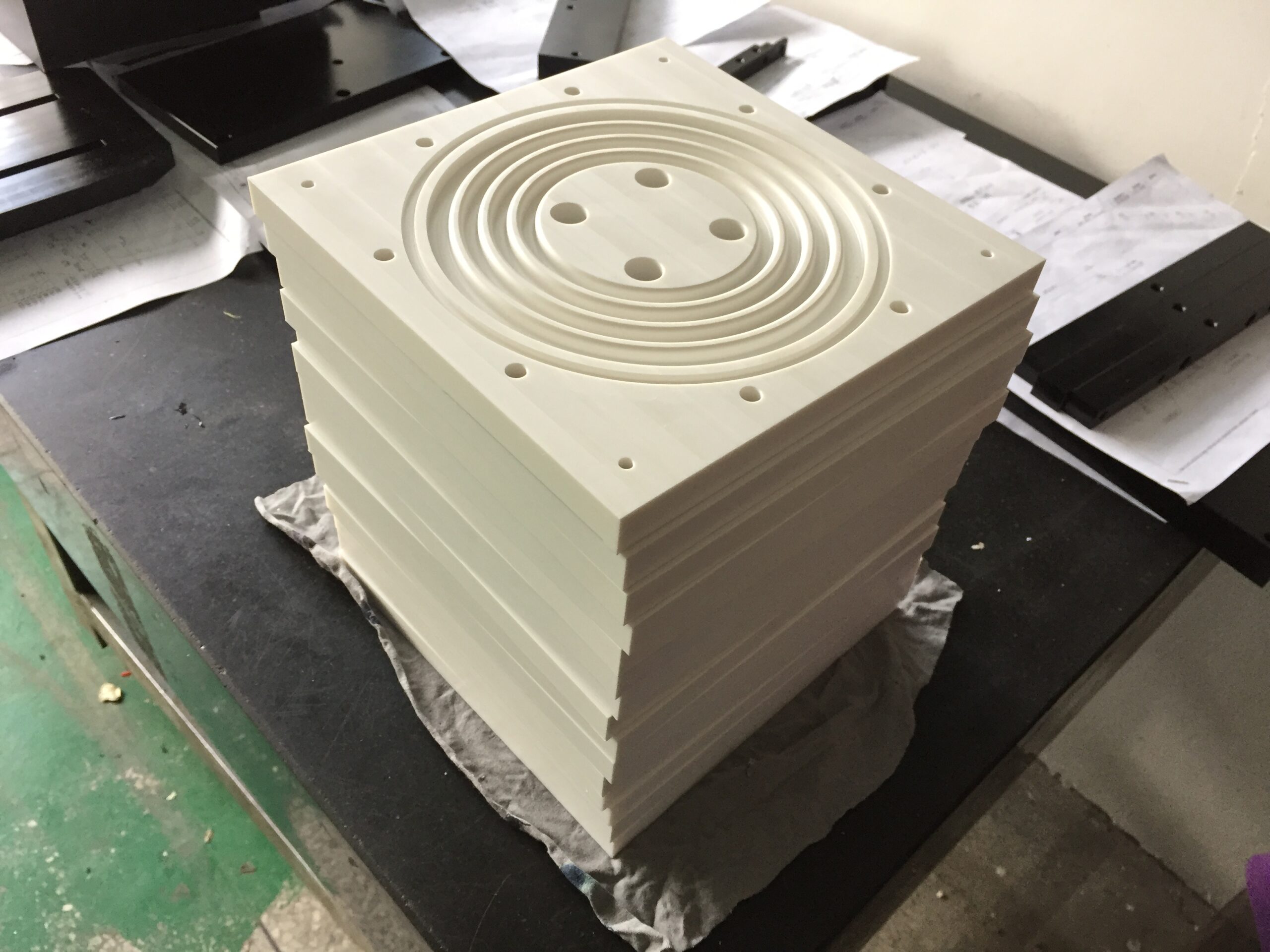

What Materials Are Suitable for CNC?

Selecting a material compatible with CNC processes is crucial.

Materials suitable for CNC include metals like aluminum, steel, brass, and plastics such as ABS, polycarbonate, and POM. These materials offer the necessary machinability and mechanical properties for diverse applications.

Common Metals for CNC Machining

- Aluminum: Lightweight, excellent machinability, corrosion-resistant.

- Steel 2: High strength, durable, available in various grades.

- Brass: Good machinability, corrosion-resistant, excellent electrical conductivity.

Common Plastics for CNC Machining

- ABS: Impact-resistant, easy to machine, cost-effective.

- Polycarbonate: High impact strength, heat-resistant, transparent.

- POM (Delrin): Low friction, wear-resistant, good dimensional stability.

| Material | Properties | Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Aerospace parts, enclosures |

| Steel | Strong, durable | Structural components |

| Brass | Conductive, corrosion-resistant | Electrical parts |

| ABS | Impact-resistant, affordable | Prototypes, consumer goods |

| Polycarbonate | Transparent, heat-resistant | Lenses, protective gear |

| POM (Delrin) | Low friction, wear-resistant | Gears, bearings |

Understanding Material Properties: Strength, Weight, and Durability

Material properties directly affect the performance of your CNC part.

Considering strength, weight, and durability helps match material properties to your project's needs, ensuring optimal performance and longevity.

Strength Considerations

Strength determines how much load a material can bear before failing.

- Yield Strength 3: The stress at which a material begins to deform plastically.

- Tensile Strength: The maximum stress a material can withstand while being stretched.

Example: Steel has a higher tensile strength than aluminum, making it suitable for heavy-duty applications requiring high load-bearing capacity.

Weight Implications

Weight affects usability, efficiency, and overall performance.

- Lightweight Materials: Aluminum is preferred in aerospace to reduce fuel consumption due to its low weight.

- Heavier Materials: Steel adds weight but provides superior strength and durability.

Durability Factors

Durability ensures the part withstands operational and environmental conditions.

- Corrosion Resistance: Materials like stainless steel and certain plastics resist rust and degradation.

- Wear Resistance: POM is ideal for parts subject to friction due to its low wear rate.

Matching Material Choices to Application Requirements

Aligning material properties with your application's demands is essential.

Select materials based on specific application requirements, considering mechanical stress, environmental exposure, and compliance standards to ensure functionality and adherence to regulations.

Assessing Functional Requirements

- Mechanical Loads: High-stress applications require materials with higher strength.

- Thermal Conditions: Materials must withstand operating temperatures without degrading.

Example: For engine components exposed to high temperatures, heat-resistant alloys 4 like Inconel are suitable.

Environmental Exposure

- Corrosive Environments: Use corrosion-resistant materials like stainless steel or specialized plastics.

- UV Exposure: UV-stable plastics 5 prevent degradation in outdoor applications.

Compliance and Standards

- Medical Applications: Biocompatible materials are necessary to meet health regulations.

- Food Industry: FDA-approved materials ensure safety and compliance.

Cost vs. Performance: Balancing Budget and Functionality

Budget constraints often influence material selection.

Balancing cost and performance involves choosing a material that meets functional needs without exceeding budget limits, optimizing both economic and technical aspects.

Material Cost Considerations

- Raw Material Prices: Exotic metals like titanium are expensive.

- Machining Costs: Harder materials increase tool wear and machining time, raising costs.

Example: Opting for aluminum over steel can reduce both material and machining expenses for non-critical components.

Performance Trade-offs

- Cost-effective Alternatives: Using plastics instead of metals when appropriate.

- Long-term Costs: Investing in durable materials can lower maintenance and replacement expenses.

Budgeting Strategies

- Prioritizing Requirements: Focus spending on critical properties that impact performance.

- Volume Discounts: Purchasing materials in bulk may reduce per-unit costs.

Environmental and Post-Processing Considerations

Environmental impact 6 and finishing processes also affect material choice.

Consider environmental factors and post-processing needs, such as finishing and coatings, to ensure the material performs well and meets aesthetic or functional requirements after machining.

Environmental Impact

- Sustainability: Opt for recyclable or eco-friendly materials to reduce environmental footprint.

- Regulatory Compliance: Adhere to environmental regulations by avoiding hazardous substances.

Post-Processing Needs

- Surface Finishing: Some materials accept coatings, anodizing, or plating better than others.

- Heat Treatment: Alters material properties like hardness and strength.

Compatibility with Finishing Techniques

| Material | Finishing Options |

|---|---|

| Aluminum | Anodizing, powder coating |

| Steel | Plating, painting, heat treatment |

| Plastics | Painting, vapor polishing |

Example: Aluminum parts can be anodized for enhanced corrosion resistance and aesthetic appeal.

Conclusion

Choosing the right material for a CNC part involves careful consideration of properties, requirements, costs, and environmental factors to ensure optimal performance and value.

-

Explains the critical considerations for selecting CNC materials, helping readers understand the impact of material properties on project success. ↩

-

Explains the types of steel suitable for CNC, helping readers choose the best grade for their project. ↩

-

Clarifies these fundamental strength parameters, helping readers choose materials based on their load-bearing requirements. ↩

-

Provides examples like Inconel for use in high-temperature environments, ensuring durability and functionality. ↩

-

Explains the benefits of UV-stable plastics in preventing material degradation in sunlight. ↩

-

Details the environmental footprint of different materials, aiding in sustainable decision-making. ↩