Struggling to select the right metal for strength-critical applications?

This guide explains metal strength types and compares common alloys for smarter engineering choices.

Don't choose a metal blindly—understand its strength first.

What Is Metal Strength and Why Does It Matter?

Not all metals are created equal—some break, some bend, and some hold strong.

Metal strength determines how much load or stress a material can handle before deforming or failing.

Dive Deeper

Understanding metal strength1 is important in engineering and manufacturing. If you pick the wrong metal, your design may fail. In my daily work with CNC parts, customers often ask me, “Is this strong enough for my application?” That question almost always starts with understanding the definition of strength.

There are different ways to measure strength. Broadly, strength is the metal’s ability to resist deformation and failure. This includes how much force it can handle before stretching, breaking, or cracking. Strength is not just about toughness or hardness. It’s a separate, measurable mechanical property.

Engineers use strength ratings to select the best metal for a project. If a part is meant to carry weight or face force, like an axle or a support bracket, strength is key. For example, using soft aluminum where hardened steel is needed will cause failure.

We should always consider strength when designing mechanical parts, tools, or housings. Choosing the right metal means better safety, longer lifespan, and reduced cost.

| Term | Meaning |

|---|---|

| Strength | General ability to resist force |

| Stress | Internal force per unit area |

| Strain | Deformation as a result of stress |

| Failure | When material breaks or deforms heavily |

Types of Metal Strength: Tensile, Yield, and Shear Strength?

Choosing a metal means knowing what kind of strength your part needs.

Tensile, yield, and shear strength are different ways to measure how metals react under stress.

Dive Deeper

In our factory, we always ask clients what kind of load their parts will face. That helps us figure out the right type of strength to look at. Here's a breakdown of the three main types:

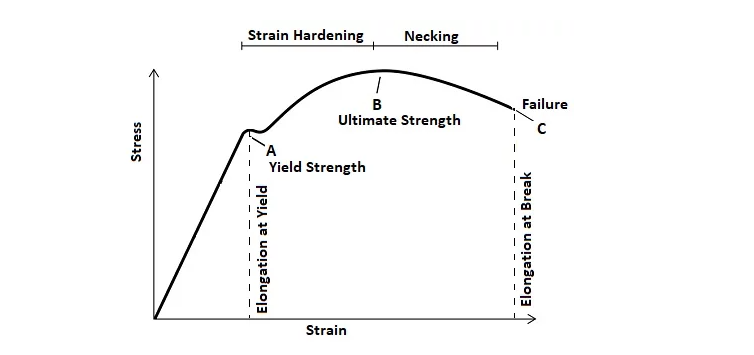

Tensile Strength2

This is the max stress a metal can withstand while being stretched. It’s often measured in megapascals (MPa) or pounds per square inch (PSI).

- Used for pulling or stretching forces

- Critical for cables, bolts, and structural parts

Yield Strength3

This is the stress point where the metal starts to deform permanently. If you want your parts to keep their shape under load, look at this number.

- Tells you when the part will bend

- Important for load-bearing parts like frames

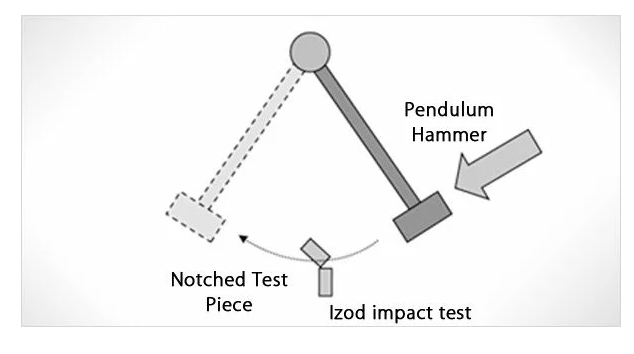

Shear Strength

This tells you how well a metal can resist sliding forces across its surface.

- Important for bolts, pins, and joints

- Lower than tensile strength in most materials

| Type of Strength | Description | Common Use Cases |

|---|---|---|

| Tensile | Resistance to pulling/stretching | Cables, rods, structural beams |

| Yield | Point of permanent deformation | Load-bearing structures |

| Shear | Resistance to side-to-side forces | Pins, rivets, fasteners |

Knowing which type matters most for your application will help narrow down your metal choice.

Key Factors That Affect Metal Strength?

Metal strength doesn’t come from magic—it’s influenced by structure, composition, and treatments.

Alloying, heat treatment, and grain size control can dramatically alter a metal’s strength.

Dive Deeper

Even the same metal can have different strength values depending on its processing. That’s why we often ask clients for more than just “I need steel.” Steel comes in many forms, and the strength varies widely.

1. Alloy Composition

Adding elements like chromium, nickel, or vanadium can improve metal strength. For example:

- Carbon increases hardness in steel

- Zinc adds strength to aluminum alloys

- Nickel improves corrosion resistance and strength in stainless steel

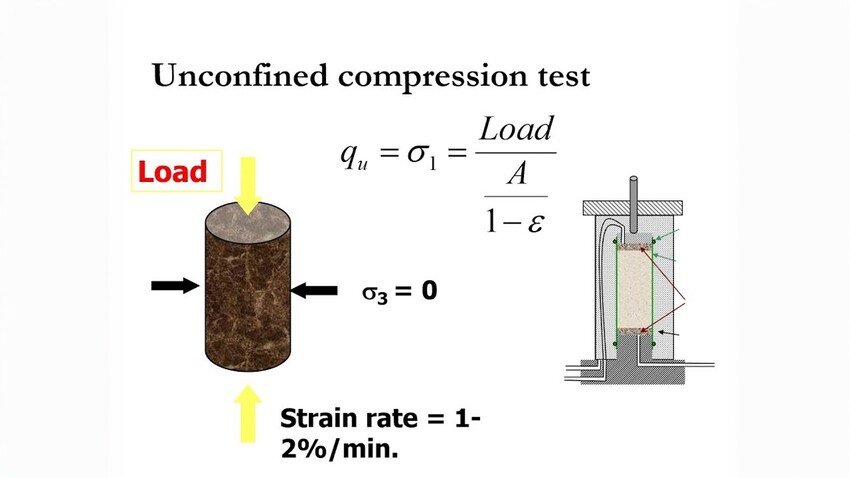

2. Heat Treatment4

Processes like quenching and tempering can make metal much stronger. In our CNC machining jobs, we often recommend post-machining heat treatments for improved performance.

3. Grain Structure5

Smaller, uniform grains usually mean higher strength. Cold working, for instance, compresses grains and improves both yield and tensile strength.

| Factor | Effect on Strength |

|---|---|

| Alloying | Changes mechanical and chemical behavior |

| Heat Treatment | Alters internal structure, boosts strength |

| Grain Refinement | Improves toughness and yield strength |

Other factors include temperature, impurities, and surface condition. Each plays a role in how strong your final part will be.

Metal Strength Comparison: Common Metals and Alloys?

How do steel, aluminum, titanium, and brass compare in strength?

Different metals serve different roles based on their mechanical strengths and cost-effectiveness.

Dive Deeper

When clients approach us for custom machining, they usually have questions like “Which metal is strongest?” or “Will this aluminum grade work?” Here's a strength-based comparison of commonly used metals:

Tensile Strength Comparison6 (MPa)

| Metal/Alloy | Tensile Strength (MPa) | Notes |

|---|---|---|

| Mild Steel | ~400 | Cheap, weldable |

| 4140 Steel | ~900 | High-strength, heat-treatable |

| 6061 Aluminum | ~310 | Lightweight, good corrosion |

| 7075 Aluminum | ~570 | Stronger, harder to machine |

| Titanium Grade 5 | ~950 | High strength, light weight |

| Brass | ~350 | Easy to machine, decorative |

Each of these materials also differs in price, availability, and weight. For example, titanium is strong but expensive. Brass is weak but easy to cut.

When choosing a metal, we help customers balance performance with cost.

How to Choose the Right Metal Based on Strength?

Too strong may be overkill, too weak may cause failure—balance is the goal.

Match the type and level of strength to the job requirements for better results and cost-efficiency.

Dive Deeper

Choosing metal strength starts with your application needs. In my experience, here’s how we help clients decide:

1. What Load Will the Part See?

If it’s under tension, look at tensile strength. If it must not bend, check yield strength.

2. What Is the Safety Margin?

High-risk applications, like aerospace or automotive, require stronger metals with high safety margins.

3. Is Weight a Concern?

High strength-to-weight ratios matter in drones, robots, or medical tools.

4. Is Machinability Important?

Some high-strength metals are hard to machine. 7075 aluminum is strong but more difficult than 6061.

Decision-Making Table

| Project Type | Recommended Metal | Reason |

|---|---|---|

| Lightweight frame | 6061 Aluminum | Light, corrosion-resistant |

| High-stress gear | 4140 Steel | Strong and wear-resistant |

| Surgical tools | Titanium Grade 5 | Biocompatible, strong |

| Aesthetic parts | Brass | Easy to shape, looks good |

We also consider client budget and delivery timelines. Sometimes, the best choice is not the strongest, but the most balanced.

Applications of High-Strength Metals in Various Industries?

Where does all that metal strength go in the real world?

High-strength metals7 are critical in aerospace, automotive, tooling, medical, and industrial machinery.

Dive Deeper

Every industry has its own standards for what “strong” means. At my factory, we make parts for all kinds of sectors, and each one values strength differently.

Aerospace

Lightweight strength is key. Titanium8 and 7075 aluminum are common.

- Aircraft brackets

- Landing gear parts

- Drone frames

Automotive

Parts need both durability and strength. Hardened steel and alloyed aluminum are popular.

- Transmission gears

- Engine mounts

- Suspension arms

Tooling and Molds

Tool steel must be extremely hard and strong to handle repeated use.

- Injection molds

- Cutting tools

- Fixtures and dies

Medical Devices

Metals must be strong, safe, and corrosion-resistant. Titanium is a favorite.

- Surgical tools

- Bone plates and screws

- Prosthetic components

Comparison Table

| Industry | Metal Commonly Used | Reason |

|---|---|---|

| Aerospace | Titanium, 7075 Al | Strength-to-weight |

| Automotive | 4140, Mild Steel | Cost and performance |

| Tooling | D2, H13 Tool Steel | High hardness |

| Medical | Titanium Grade 5 | Biocompatibility and strength |

Matching the strength to the industry's real-world needs is what makes parts succeed in the field.

Conclusion

Understanding metal strength helps engineers make better design choices, reduce failure, and improve product performance.

-

Understanding metal strength is crucial for selecting the right materials in engineering, ensuring safety and durability in designs. ↩

-

Tensile strength is vital for applications involving stretching forces; knowing it helps in choosing the right materials for structural integrity. ↩

-

Yield strength indicates when a metal will deform, making it essential for load-bearing applications to ensure reliability and performance. ↩

-

Heat treatment is a key process that can significantly enhance metal strength. Discover more about its techniques and benefits. ↩

-

Grain structure plays a vital role in determining metal strength. Learn how it impacts performance and durability. ↩

-

Understanding tensile strength is crucial for selecting the right metal for your project. Explore this link for detailed comparisons and insights. ↩

-

Explore how high-strength metals are utilized across different sectors, enhancing performance and safety in critical applications. ↩

-

Discover the unique properties of titanium that make it essential in aerospace and medical fields, ensuring safety and efficiency. ↩