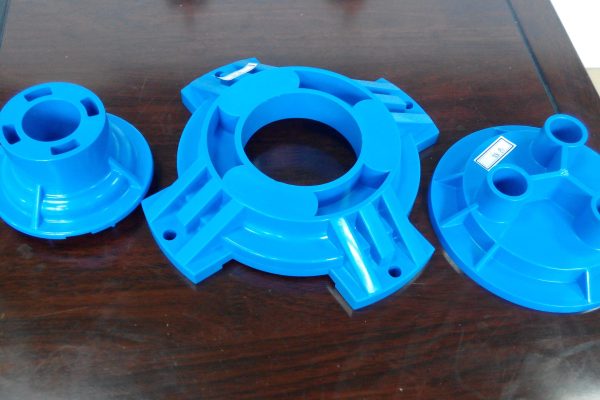

World-Class Plastic Molding Services

Custom Injection Molding for Every Project Size

From rapid tooling to high-volume production tooling, we deliver reliable, high-quality services with expert support at every step.

What is Plastic Molding?

CNC machining involves using computer-controlled tools to precisely remove material from a workpiece. Its advanced automation ensures faster, more accurate, and more reliable results compared to traditional methods.

Plastic Molding at Elue Industry

Our comprehensive injection molding services cover every aspect of production—from raw material testing and toolmaking to part fabrication, finishing, and inspection. Whether you need prototypes or high-volume production, we provide precise solutions optimized for your timeline and budget.

Our Injection Molding Services

At Elue Industry, we offer a comprehensive range of injection molding solutions tailored to your unique needs. From rapid prototyping and low-volume production to high-volume manufacturing, our advanced processes and experienced team ensure precision, efficiency, and exceptional quality at every step. Whether you require simple parts or complex multi-material assemblies, we have the expertise to bring your ideas to life.

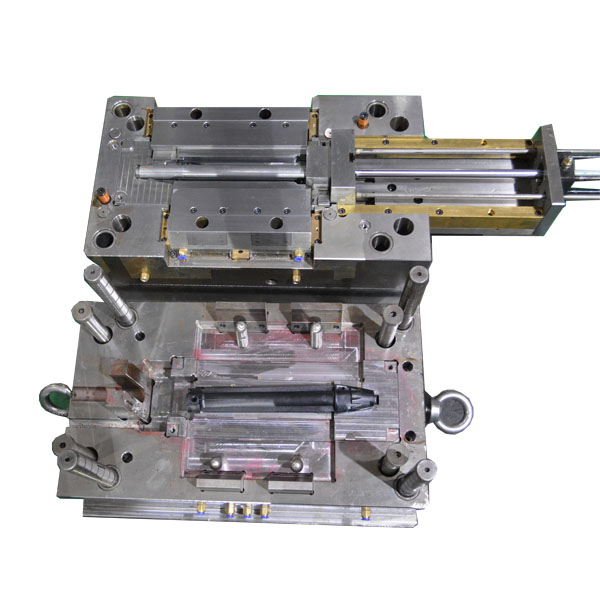

Production Tooling

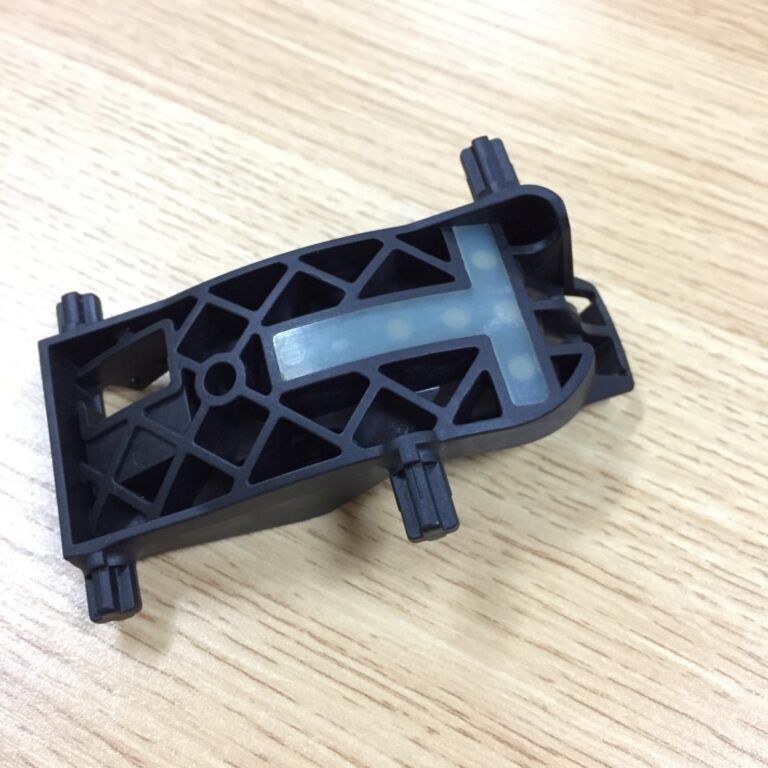

Overmolding

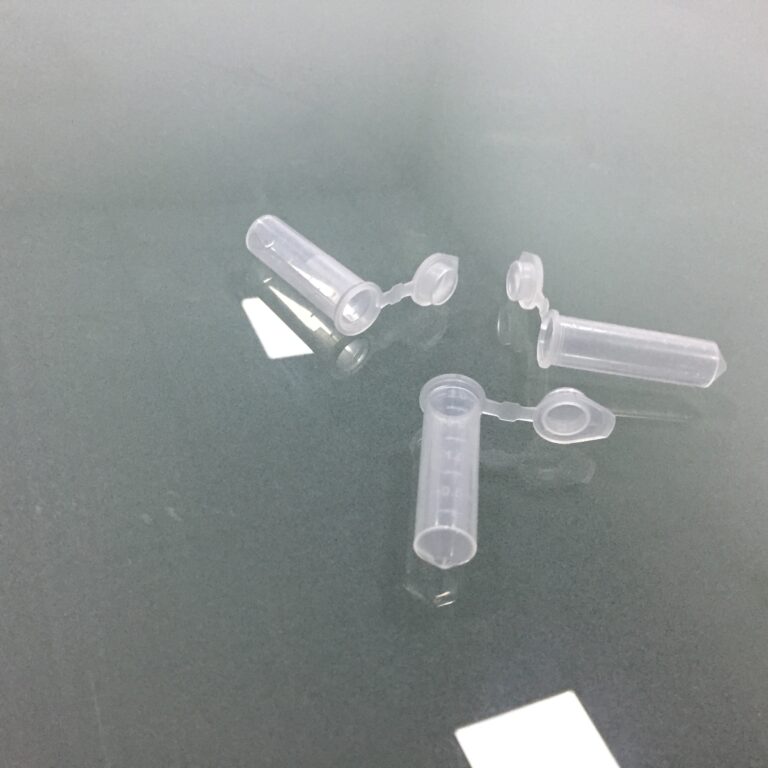

Insert Molding

Using premium tool steels and advanced engineering, we create durable molds that ensure repeatable results and long production life.

Overmolding combines multiple materials into a single part, enhancing functionality and aesthetics. This process is ideal for creating ergonomic grips, sealing components, or multi-color designs.

Insert molding integrates metal inserts, threads, or other components into molded plastic parts. It’s an efficient way to produce robust and complex assemblies in a single step.

About Shanghai Elue

Why Choose Elue for Injection Molding?

Complete Manufacturing Solutions

We provide a full suite of services, from toolmaking and part production to finishing and inspection, ensuring end-to-end support for your projects.

Proven Track Record

Elue Industry has successfully supported hundreds of companies worldwide in creating injection-molded tools and components.

Advanced Material Testing

Our industry-leading material verification ensures your parts meet all specifications and regulatory requirements.

Design Optimization

Every project includes a thorough Design for Manufacturability (DFM) review, saving you time and money while delivering superior results.

Industries We Serve

Elue Industry provides injection molding solutions for a wide range of industries. Our expertise and advanced manufacturing capabilities ensure high-quality, custom parts tailored to meet the specific requirements of each sector.

Automotive

Home Appliances

Medical Devices

Precision-molded components for vehicles, including interior trims, under-hood parts, and functional assemblies. Our durable molds meet the strict standards of the automotive industry for quality and performance.

Custom plastic parts for refrigerators, washing machines, and other household appliances. We deliver robust, aesthetically pleasing components that enhance product functionality and design.

High-precision parts for medical equipment, surgical tools, and healthcare applications. Our ISO-certified processes ensure compliance with stringent industry standards for safety and reliability.

Consumer Electronics

Agriculture

Industrial Equipment

Plastic enclosures, keypads, and components for electronic devices. Our injection molding services provide sleek, durable, and functional parts for cutting-edge consumer products.

Plastic parts for irrigation systems, equipment housings, and farming tools. Our injection molding services provide rugged, weather-resistant components designed for outdoor and heavy-duty use.

Molded parts for machinery, automation systems, and industrial tools. We specialize in creating strong, wear-resistant components that can withstand demanding operating conditions.

Advantages of Injection Molding

From Shanghai Elue

We’re equipped with 20 sets injection machines, from 80 ton to 600 ton. With thousands of material options, customizable designs, and reliable production capabilities, we help you achieve superior results with every project.

Partner with us for seamless manufacturing, unmatched quality, and on-time delivery.

- Extensive Material Options: Thousands of resins for versatile applications

- Highly Automated Processes: Ensures efficiency and cost-effectiveness.

- Stable and Repeatable: Reliable results for every production run.

- Excellent Surface Finishes: Achieve superior appearance and performance.

- Overmolding Options: Expand design possibilities with multi-material solutions

- Multi-Cavity Tools: Enhance production efficiency for large volumes.

Plastic Molding FAQs

1. What types of plastic molding do you offer?

We specialize in injection molding, blow molding, and insert molding, catering to different production needs and material requirements.

3. What is the lead time for plastic molded parts?

Lead time varies depending on the complexity and volume of your project. Typically, molds can be finished within 3-4 weeks, while production runs take another 1-2 weeks.

5. What is your maximum production capacity for plastic molding?

We can handle both low-volume runs (as few as 1000 units) and high-volume production runs, scaling up to hundreds of thousands of parts.

6. What surface finishes can you provide for molded parts?

We offer a variety of surface finishes, such as polishing, texturing, painting, silk-screening, and custom coatings, to meet your aesthetic and functional needs.

8. What typical tolerances can you achieve in plastic molding?

We can achieve tolerances as tight as ±0.01mm, depending on the material and part complexity. Specific tolerances can be discussed during the design phase.

2. What materials can you use for plastic molding?

We work with a variety of plastics, including ABS, PC, POM, Nylon, PP, PVC, Acrylic, and custom resins based on project requirements.

4. Can you assist with the design and development of molds?

Yes, our engineering team provides complete support for mold design, optimization, and prototyping to ensure efficient production and high-quality results.

7. How do you ensure quality in plastic molding?

We employ rigorous quality control measures, including material inspections, dimensional checks, and in-process monitoring, to ensure precision and consistency.

9. Can I use recycled plastics for my molded parts?

Yes, we can use recycled plastics depending on the application and performance requirements. Our team can guide you in selecting the best sustainable option for your project.

10. Do you offer secondary operations for molded parts?

Yes, we provide secondary operations such as assembly, ultrasonic welding, drilling, and custom packaging to deliver a complete end-to-end solution.