At ELUE Industry, quality is at the heart of everything we do. With ISO9001 and IATF16949 certifications, we adhere to strict quality management standards to ensure every part meets or exceeds your expectations.

From raw material verification to final inspections, our dedicated team and advanced equipment guarantee unparalleled precision and reliability.

We implement a comprehensive quality control process to ensure every project is delivered with excellence.

Here’s how we maintain the highest standards:

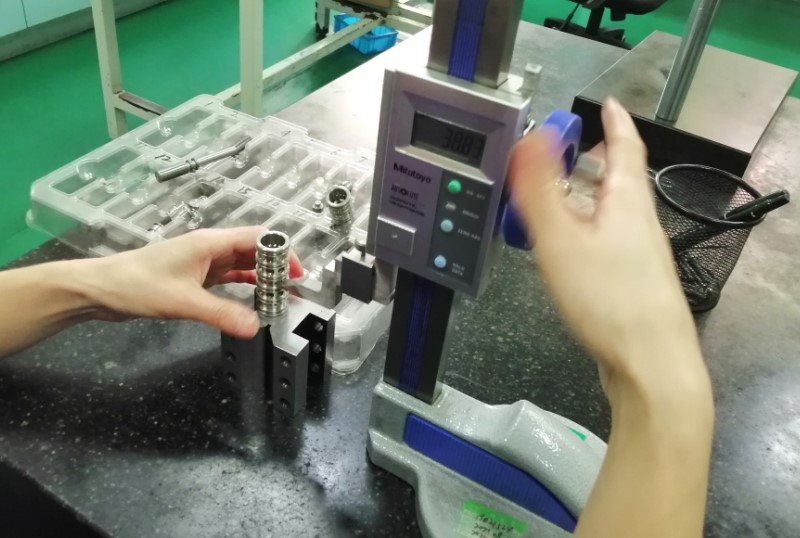

Equipped with state-of-the-art inspection tools, we ensure every part meets your precise specifications.

Our capabilities include:

Profile projectors are precision optical devices that magnify and project the silhouette of a part onto a screen for dimensional analysis. These tools are perfect for inspecting small, intricate components with fine details that are difficult to measure with traditional methods.

Our profile projectors help ensure consistent quality for parts such as gears, fasteners, and precision tools, offering visual clarity and accurate dimensional assessments.

A specialized instrument used to measure and quantify the surface texture of a part. Surface roughness is critical in applications where friction, wear resistance, or aesthetic appeal is a key requirement.

With our roughness testers, we can achieve measurements as low as Ra 0.2μm, ensuring parts meet stringent requirements for medical implants, aerospace components, and other high-precision applications.

An essential device for determining a material’s resistance to deformation under load, ensuring it meets strength and durability standards. We use hardness testers to verify the mechanical properties of metals and alloys used in demanding applications.

Our hardness testing capabilities cover a range of scales, including Rockwell, Vickers, and Brinell, providing reliable data to ensure the long-term performance of your components.

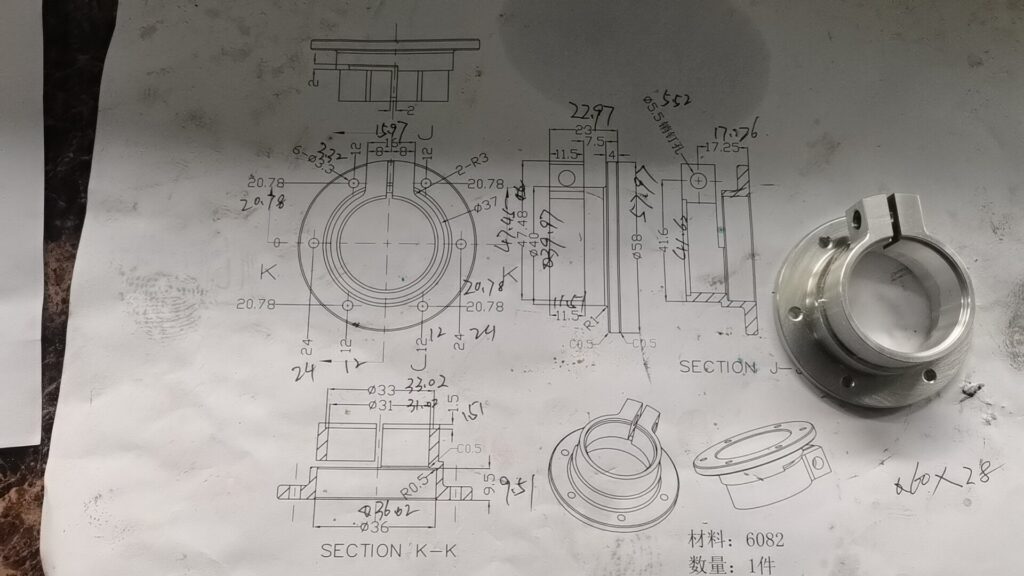

Challenge: Achieving tight tolerances for lightweight yet durable parts.

Solution: Used advanced CMM inspections to ensure ±0.01mm accuracy across all components.

Challenge: Ensuring biocompatibility and flawless surface finishes.

Solution: Delivered 100+ implants with Ra 0.2μm finishes, fully compliant with medical standards.

Get the latest updates via email. Don’t miss it. Any time you may unsubscribe.